Silo Cleaning

Professional Silo Cleaning Services- Tierra Environmental

Specialized Industrial Storage Cleaning Solutions for Over Two Decades

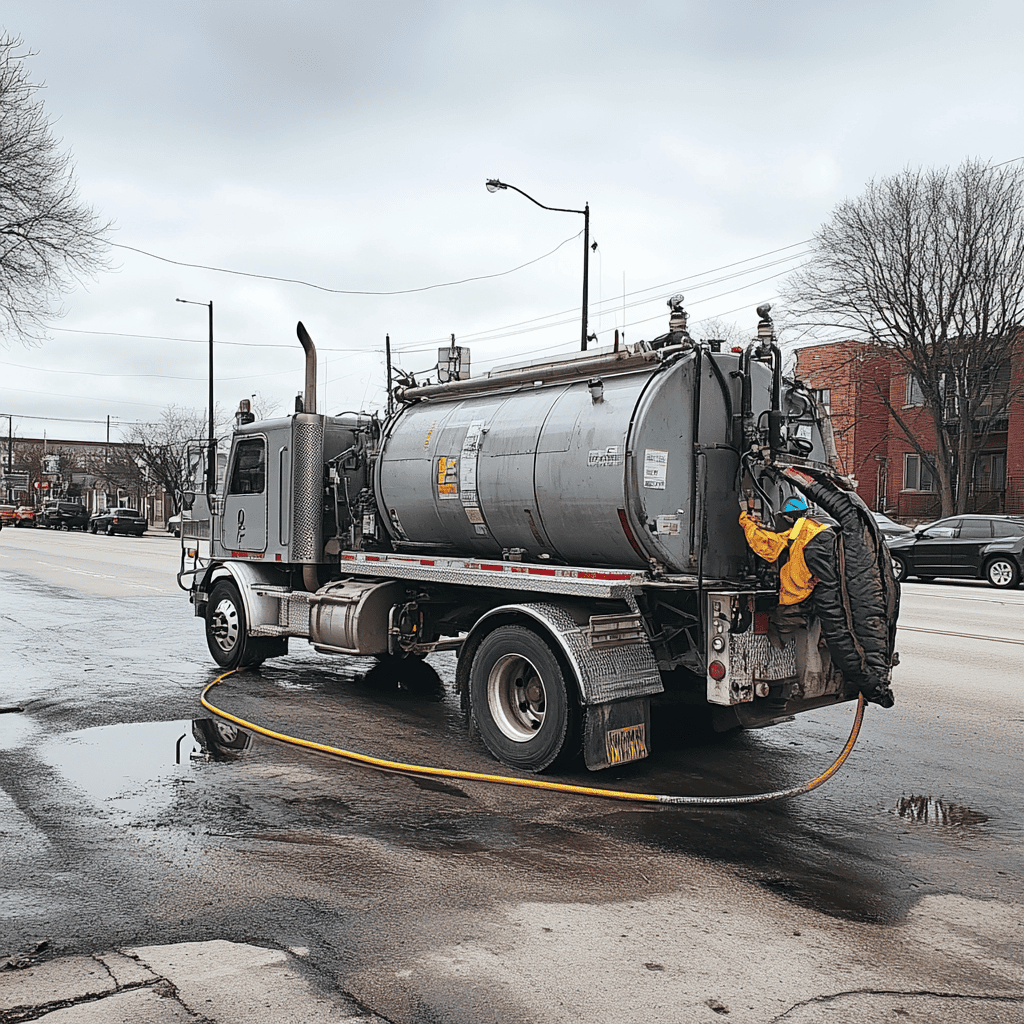

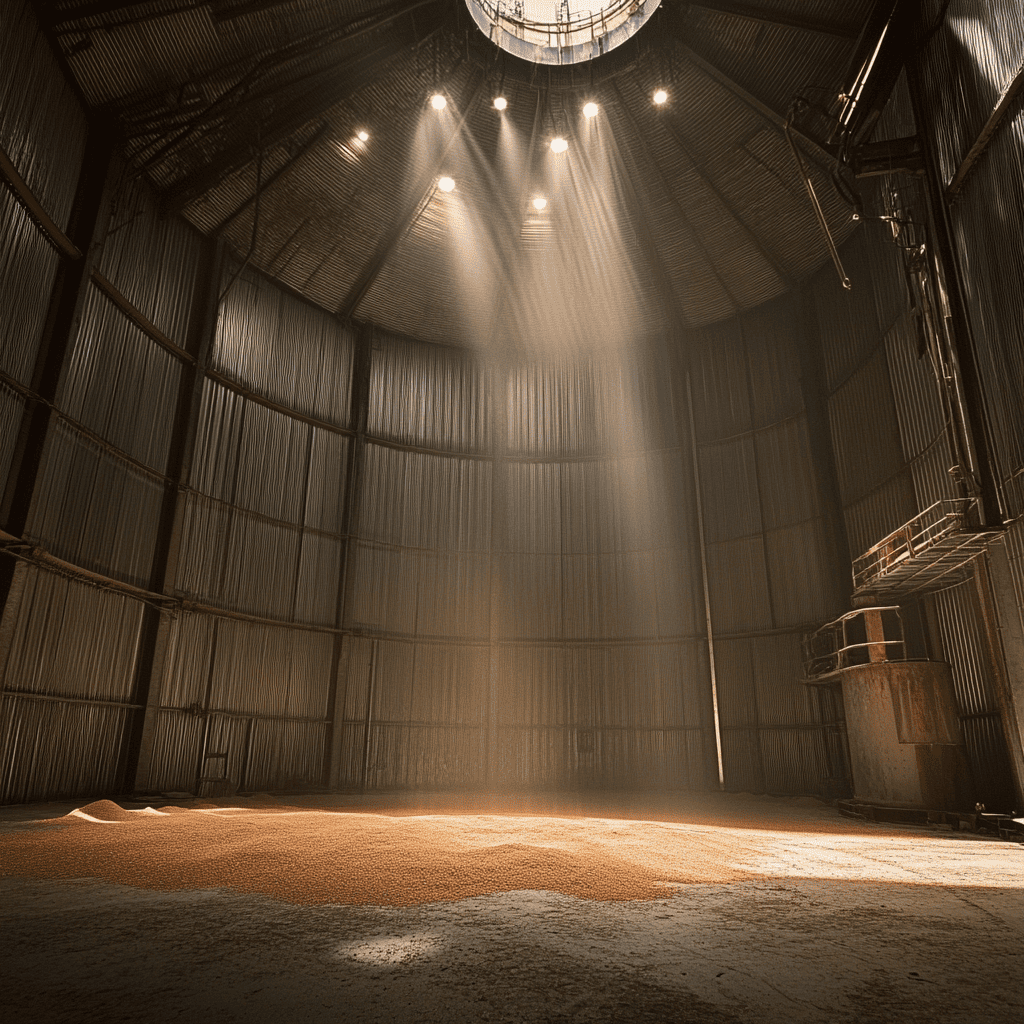

Tierra Environmental Services delivers professional silo cleaning throughout Indiana and the Midwest region, helping agricultural facilities, food processing plants, manufacturing operations, and industrial complexes maintain clean, safe, and efficiently operating storage systems. Our certified technicians specialize in complete silo cleaning that removes accumulated materials, prevents contamination, and maintains food safety standards while minimizing operational downtime. With our advanced pneumatic systems and confined space expertise, facility managers can maintain productive operations while we handle the complex task of thorough silo maintenance.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

Why Professional Silo Cleaning Is Required for Industrial Operations

Our Silo Cleaning Services Include:

Complete Material Removal and Cleanout

Pneumatic Cleaning and Debris Extraction

Confined Space Entry and Interior Inspection

Structural Assessment and Component Inspection

Sanitization and Food Safety Compliance

Trust Tierra Environmental for All Your Cleaning Needs

Benefits of Regular Professional Silo Cleaning

Prevents Product Contamination and Quality Issues

Maintains Storage Capacity and Flow Efficiency

Supports Regulatory Compliance and Safety Standards

Prevents Equipment Damage and Operational Failures

Reduces Fire and Explosion Hazards

Understanding Silo Design and Cleaning Requirements

Material Types and Storage Challenges

Hygroscopic materials absorb moisture that can cause caking and bridging while creating conditions for bacterial growth and spoilage. Understanding these material characteristics helps facility managers appreciate why different storage systems require customized cleaning approaches rather than standard procedures that may not address specific contamination risks.

Silo Configuration and Access Considerations

Access limitations often determine cleaning methods, with some silos requiring confined space entry while others can be cleaned using external equipment. Our technicians evaluate each facility’s specific configuration to develop cleaning procedures that address all areas while maintaining safety requirements and minimizing operational disruption.

Cleaning Frequency Based on Usage Patterns

Seasonal usage patterns also influence cleaning schedules, with agricultural facilities often requiring intensive cleaning during harvest transitions, while manufacturing operations may need regular maintenance throughout the year. Our technicians work with facility managers to develop cleaning schedules that support operational requirements while maintaining storage system efficiency.

Safety Protocols for Silo Cleaning Operations

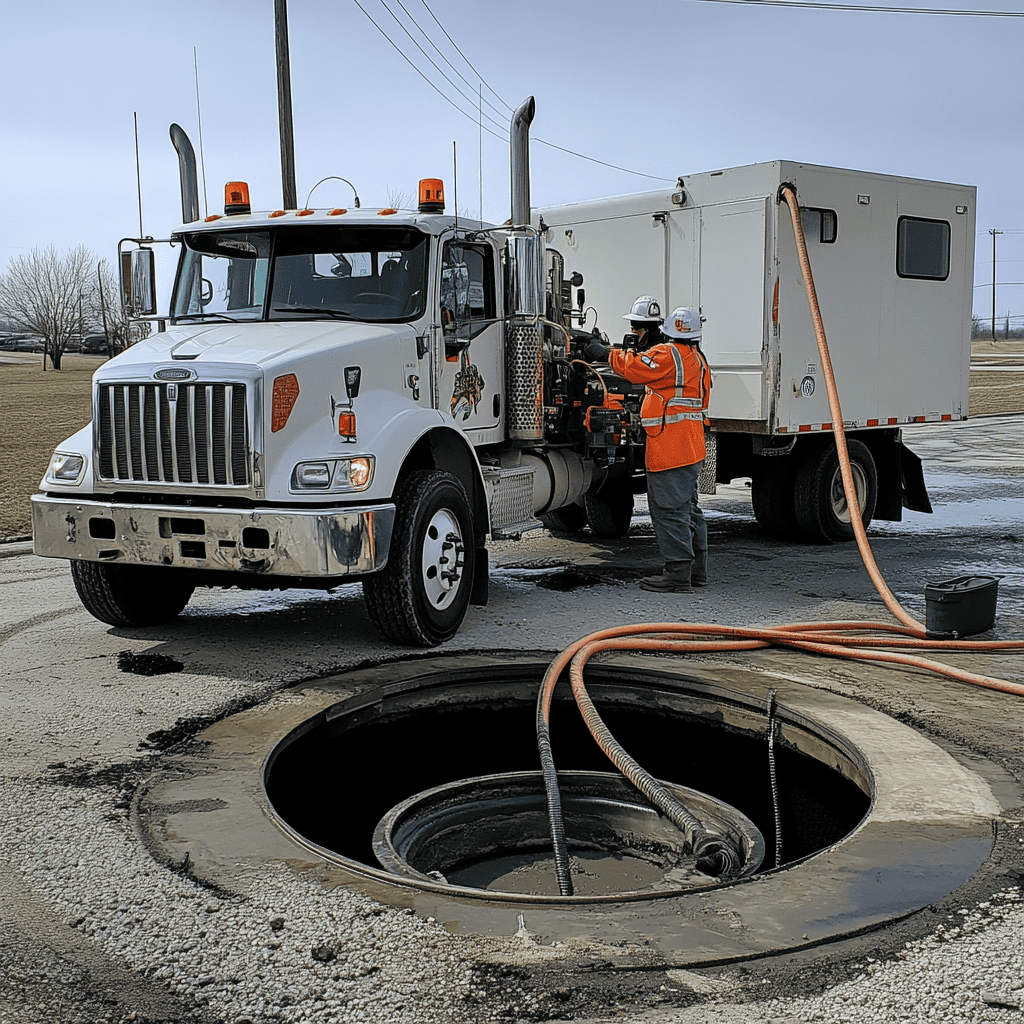

Confined Space Entry Procedures

Entry permits are required for all confined space operations, with detailed documentation of atmospheric conditions, safety equipment, and personnel assignments. We never allow single-person entry operations and maintain constant communication between interior and exterior personnel during all cleaning activities. These safety protocols protect workers while meeting OSHA requirements for confined space operations.

Atmospheric Monitoring and Ventilation

Proper ventilation systems remove contaminated air while supplying fresh air to maintain safe atmospheric conditions during interior operations. We use specialized ventilation equipment designed for confined space applications while maintaining proper air circulation that prevents the accumulation of hazardous gases or dust. This ventilation capability supports safe working conditions while enabling thorough cleaning of interior surfaces.

Fall Protection and Emergency Response

Emergency response procedures include communication systems, rescue equipment, and coordination with local emergency services when necessary. We maintain detailed emergency action plans for each facility while coordinating with site safety personnel to ensure rapid response capabilities. This emergency preparedness protects personnel while meeting regulatory requirements for high-risk operations.

Specialized Equipment and Cleaning Technologies

Pneumatic Cleaning Systems

The pneumatic approach allows precise control of cleaning intensity while directing removal efforts to specific problem areas. Our equipment includes variable pressure controls and specialized nozzles designed for different material types and silo configurations. This flexibility enables thorough cleaning while protecting expensive silo infrastructure from damage during cleaning operations.

Vacuum Collection and Material Handling

Material handling capabilities include proper segregation of different materials and contaminated waste to prevent cross-contamination and support proper disposal requirements. We provide temporary storage containers and transportation services that handle all removed materials according to applicable regulations while supporting facility waste management programs.

Confined Space Ventilation Equipment

Ventilation equipment includes both supply and exhaust systems that maintain proper air circulation while preventing the accumulation of hazardous gases or dust. We monitor airflow continuously during operations while adjusting ventilation rates based on atmospheric conditions and work requirements. This ventilation capability enables safe completion of complex cleaning projects that require extensive interior access.

Trust Tierra Environmental for All Your Cleaning Needs

Industry Applications and Specialized Solutions

Agricultural and Grain Storage Facilities

Harvest season transitions often require rapid cleaning to prepare storage systems for new crops while preventing cross-contamination between different grain types. We provide flexible scheduling that accommodates harvest timing while maintaining thorough cleaning standards that protect product quality. Our agricultural expertise includes an understanding of commodity requirements and quality standards that affect cleaning procedures.

Food Processing and Manufacturing

Processing facilities often require cleaning between product runs to prevent cross-contamination while maintaining allergen control programs. We provide rapid response cleaning that minimizes production downtime while maintaining thorough sanitation standards. Our food safety expertise includes an understanding of HACCP requirements and allergen management that affects cleaning procedures.

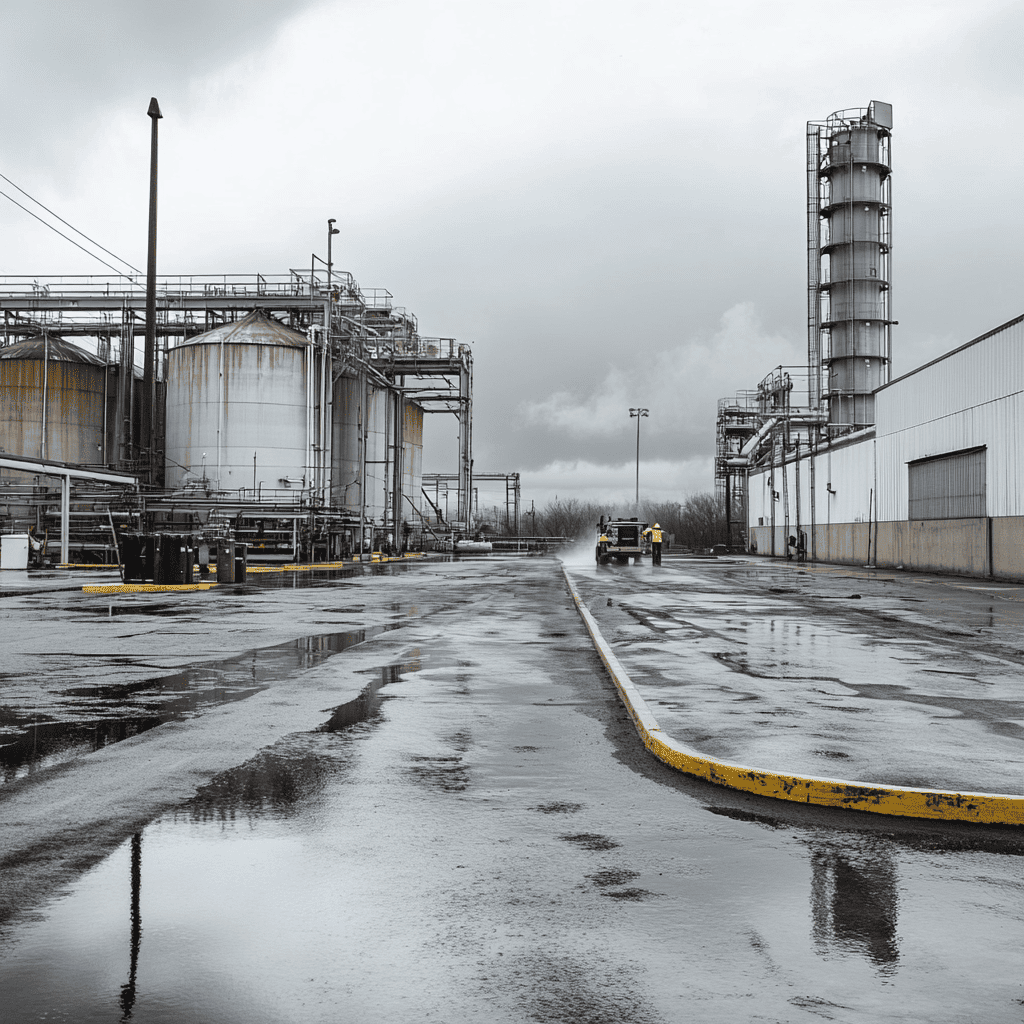

Chemical and Industrial Storage

Industrial facilities often store multiple chemical products that require complete cleaning between different materials to prevent dangerous reactions or contamination. We provide comprehensive cleaning that removes all residues while properly handling and disposing of chemical wastes according to applicable regulations. Our chemical expertise includes an understanding of material compatibility and safety requirements that affect cleaning procedures.

Cleaning Process and Service Standards

Pre-Cleaning Assessment and Planning

Planning includes coordination with facility operations to minimize production disruption while maintaining safety requirements throughout cleaning operations. We develop detailed work plans that address scheduling, equipment placement, and safety procedures while coordinating with facility personnel. Proper planning ensures efficient cleaning completion while maintaining operational continuity for essential facility functions.

Safe Material Removal and Extraction

Removed materials are properly segregated and contained to prevent contamination while supporting appropriate disposal or recycling programs. We provide documentation of material types and quantities removed while coordinating disposal activities with facility waste management programs. This material handling approach protects environmental compliance while supporting facility sustainability goals.

Interior Cleaning and Sanitization

Sanitization procedures use approved disinfectants and cleaning agents that eliminate bacteria, mold, and other contaminants while meeting applicable food safety or industrial standards. We document sanitization activities with appropriate testing and verification procedures that demonstrate compliance with regulatory requirements. This sanitization process protects product quality while supporting facility quality assurance programs.

Final Inspection and Documentation

Service documentation includes detailed reports suitable for regulatory compliance, insurance requirements, and facility quality assurance programs. We provide photographic documentation, material disposal certificates, and cleaning verification that demonstrates proper service completion. This comprehensive documentation protects facilities during audits while supporting compliance with applicable regulations.

Maintenance Programs and Scheduling Options

Preventive Cleaning Schedules

Scheduling flexibility accommodates seasonal variations in storage needs while maintaining regular cleaning intervals that prevent material accumulation. Our preventive programs include monitoring of storage conditions and early identification of cleaning needs that help facilities avoid emergencies. This proactive approach reduces cleaning costs while maintaining operational reliability.

Emergency Response and Rapid Cleaning

Emergency services include 24/7 availability for critical situations that threaten facility operations or regulatory compliance. We maintain fully equipped response vehicles and certified personnel ready to address any silo emergency while coordinating with facility personnel to minimize operational impact. This rapid response capability protects facility operations while maintaining safety and compliance requirements.

Customized Service Programs

Service programs can include maintenance contracts that provide scheduled cleaning, emergency response, and equipment inspection services at fixed costs that support facility budgeting requirements. We work with facility managers to develop programs that address specific operational needs while maintaining regulatory compliance and safety standards. These programs provide comprehensive silo maintenance support while reducing administrative burden on facility personnel.

Trust Tierra Environmental for Professional Silo Cleaning

Let our experienced team handle your silo cleaning requirements so you can focus on production operations and facility management. Our comprehensive safety protocols, specialized equipment, and emergency response capabilities provide the support your facility needs to maintain clean storage systems while meeting all regulatory and safety requirements.

Trust Tierra Environmental for All Your Cleaning Needs

Frequently Asked Questions

How often should industrial silos be professionally cleaned?

- High-turnover grain storage: Every 6-12 months, depending on material type

- Food processing silos: Between product changes or quarterly

- Chemical storage systems: Based on material characteristics and regulations

- Seasonal agricultural use: Before each harvest season

- Multi-product facilities: Between different material types

What safety certifications do your technicians hold for silo cleaning?

- OSHA 10 and OSHA 30 general safety training

- Confined Space Entry certification for interior operations

- HAZMAT operations certification for chemical materials

- Fall protection and rescue training

- Atmospheric monitoring equipment certification

Can you clean silos containing hazardous materials?

- Chemical powders and residues

- Toxic or corrosive materials

- Combustible dust and grain products

- Materials requiring special disposal procedures

What happens to materials removed during silo cleaning?

- Reusable materials may be returned to storage or processing systems

- Contaminated materials are disposed of at licensed facilities

- Hazardous waste follows strict disposal protocols with proper documentation

- Organic materials may be composted where appropriate

- Chemical residues require specialized disposal procedures

Do you provide cleaning for food-grade storage systems?

- Use of approved cleaning agents and sanitizers

- Complete removal of allergens and contaminants

- Documentation suitable for food safety audits

- HACCP compliance support

- Sanitary equipment and procedures

How long does silo cleaning typically take?

- Small grain silos: 1-2 days for standard cleaning

- Large industrial silos: 3-5 days depending on material buildup

- Multi-compartment systems: Extended time for each section

- Confined space requirements: Additional time for safety procedures

- Material characteristics: Hardened deposits require more time

Can you clean silos without facility shutdown?

- Flexible scheduling around production requirements

- Sectional cleaning of multi-compartment systems

- Rapid cleaning procedures for time-sensitive operations

- Coordination with facility operations personnel

- Emergency procedures for urgent cleaning needs

What documentation do you provide after silo cleaning?

- Service reports with detailed cleaning procedures performed

- Material removal quantities and disposal certificates

- Photographic documentation of before-and-after conditions

- Safety compliance records for confined space operations

- Inspection reports with maintenance recommendations

- Regulatory compliance verification is suitable for audits

Do you offer emergency silo cleaning services?

- Material blockages preventing normal discharge

- Contamination issues threatening product quality

- Safety hazards requiring immediate attention

- Regulatory compliance emergencies

- Equipment failures affecting storage operations

How do you handle different types of stored materials?

- Grain products: Focus on mold prevention and pest elimination

- Flour and powders: Address caking and dust accumulation

- Chemicals: Follow hazmat protocols and disposal requirements

- Food ingredients: Maintain sanitary conditions and allergen control

- Industrial materials: Address specific contamination and safety concerns