Hydro Jetting

Professional Hydro Jetting Services - Tierra Environmental

High-Pressure Drain and Sewer Cleaning Solutions for Indiana Businesses and Municipalities

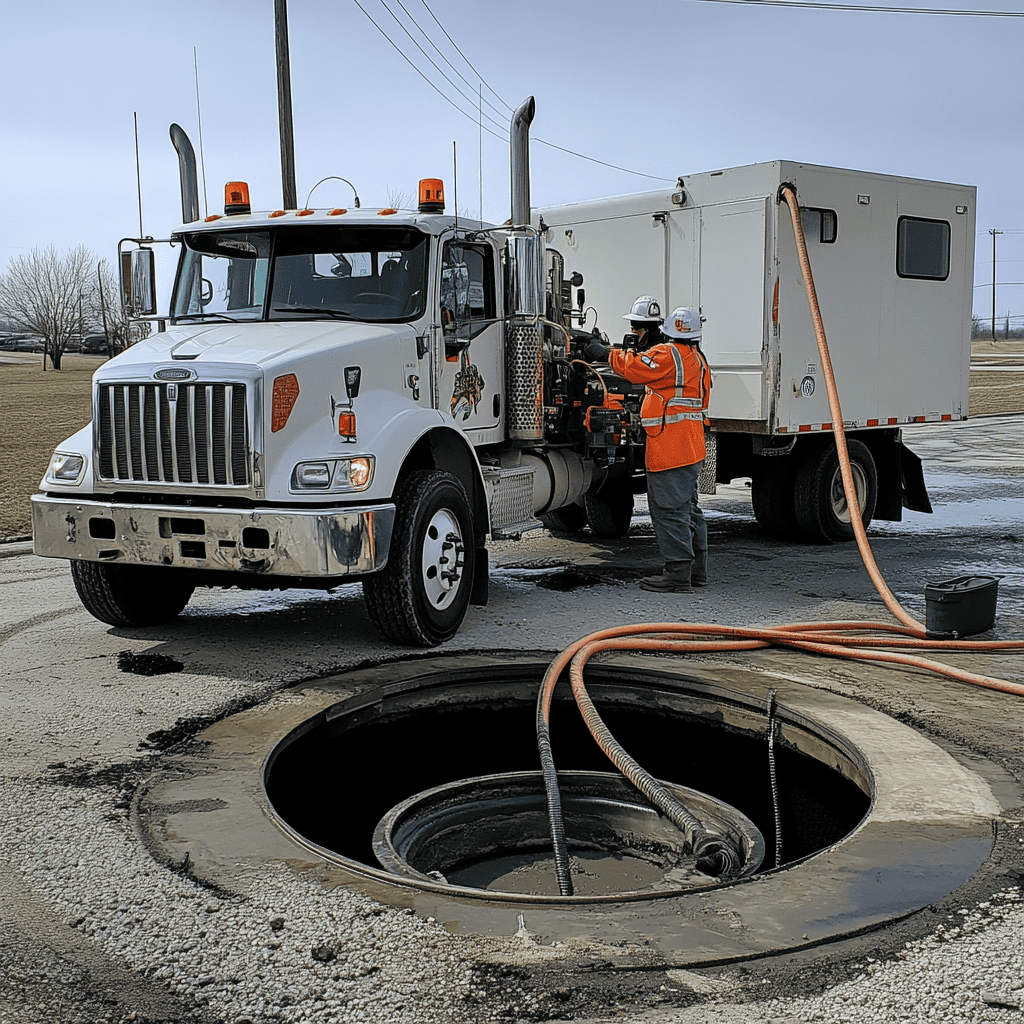

Tierra Environmental Services provides professional hydro jetting services throughout the Midwest region, delivering powerful high-pressure water cleaning solutions that effectively clear the most stubborn blockages from commercial and municipal sewer systems. Our certified technicians utilize advanced hydro jetting equipment to restore proper flow in drain lines, storm sewers, and industrial piping systems that conventional cleaning methods cannot address. With specialized vacuum trucks and high-pressure jetting units, we tackle complex blockages caused by grease accumulation, root intrusion, mineral deposits, and industrial debris that threaten operational efficiency and environmental compliance.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

What Is Hydro Jetting and How Does It Work?

Hydro jetting employs high-pressure water streams, typically ranging from 1,500 to 4,000 PSI, to scour pipe walls and remove accumulated debris, grease, and blockages from sewer and drain systems. This process uses specialized nozzles that direct pressurized water in multiple directions, creating a scouring action that effectively removes buildup while flushing debris downstream for collection and removal. Unlike mechanical cleaning methods that may only punch holes through blockages, hydro jetting completely cleans pipe walls and restores full pipe capacity.

The hydro jetting process begins with a thorough pipe inspection using advanced camera equipment to identify blockage locations, pipe condition, and any structural issues that might affect cleaning procedures. Our technicians select appropriate nozzle configurations based on pipe size, blockage type, and desired cleaning results. The high-pressure water effectively cuts through grease deposits, removes root intrusions, and eliminates scale buildup while being environmentally safe and chemical-free.

Advanced Nozzle Technology for Maximum Cleaning Effectiveness

Different nozzle designs address specific cleaning challenges, with some creating powerful forward thrust for blockage penetration while others focus on thorough wall cleaning action. Our technicians select optimal nozzle combinations based on inspection findings and specific cleaning objectives, ensuring maximum effectiveness while protecting pipe integrity. This technical expertise allows us to address diverse cleaning challenges with precision and efficiency.

Our Professional Hydro Jetting Services Include:

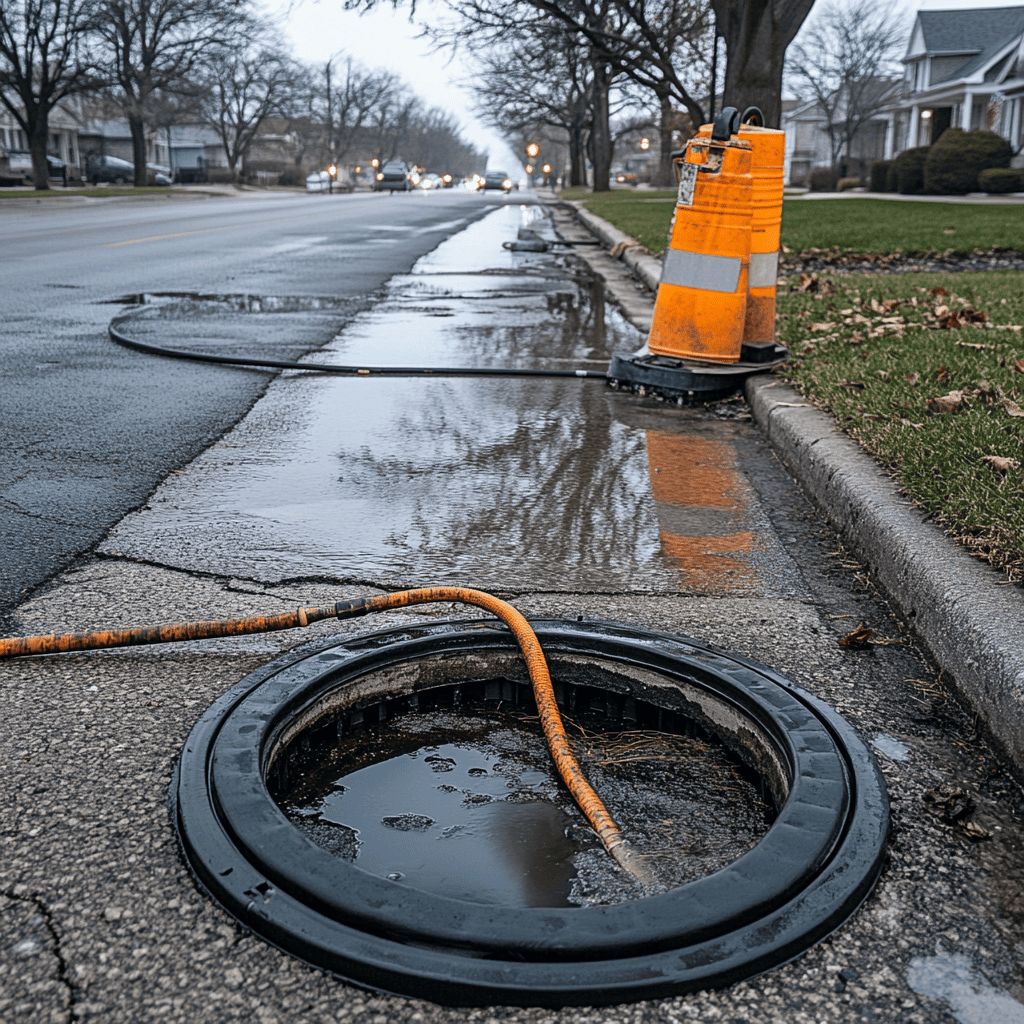

Municipal Storm Sewer System Cleaning

Storm sewer cleaning requires specialized techniques that address unique challenges, including varying pipe sizes, access limitations, and environmental protection requirements. Our certified technicians coordinate with municipal authorities to schedule cleaning activities that minimize traffic disruption while maintaining emergency response capabilities. We provide detailed documentation of cleaning activities and system conditions that support municipal maintenance planning and regulatory compliance requirements.

Commercial Sewer Line Restoration

Our commercial hydro jetting services include thorough line inspection, complete blockage removal, and preventive cleaning programs that maintain optimal flow conditions. We work with facility managers to schedule cleaning activities during low-impact periods while providing emergency response capabilities for urgent blockage situations. Regular hydro jetting prevents costly backups while maintaining compliance with local discharge regulations and environmental protection requirements.

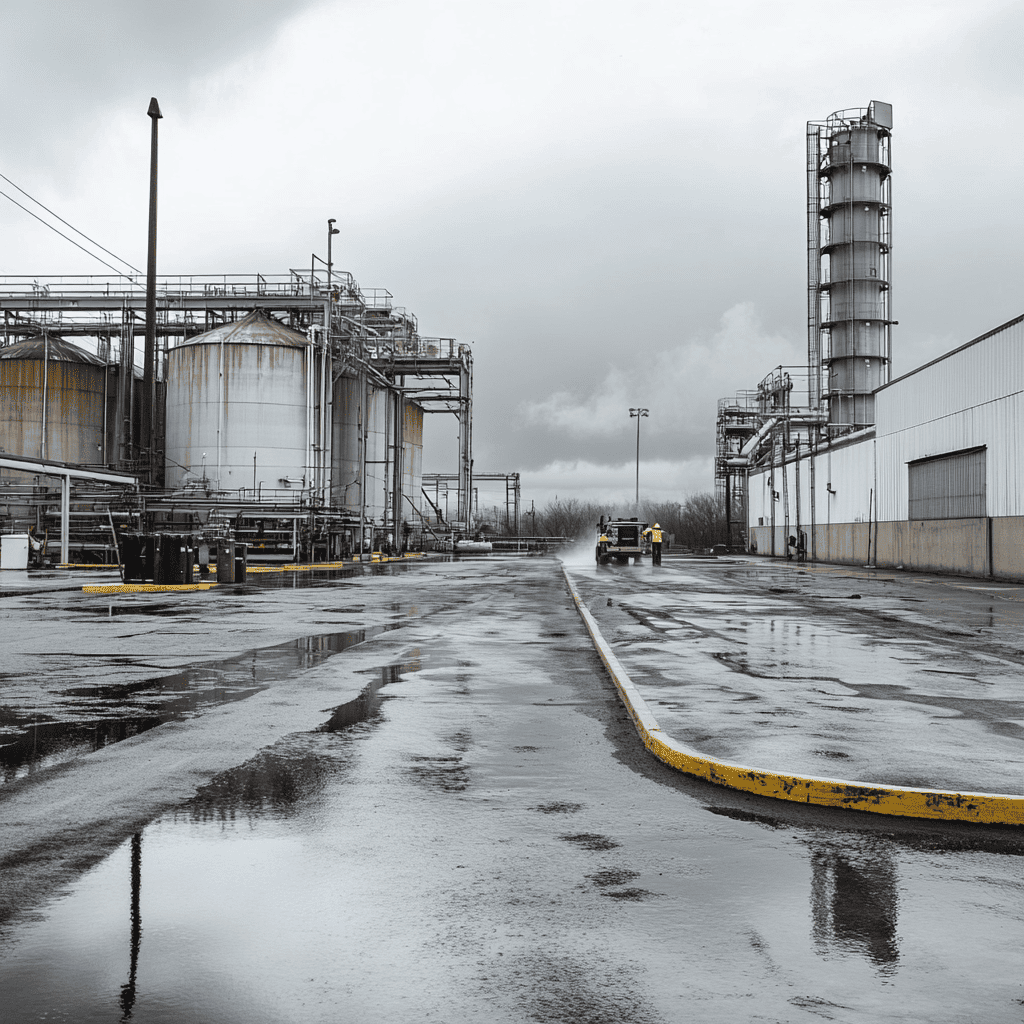

Industrial Piping System Cleaning

Industrial hydro jetting requires specialized safety procedures, chemical compatibility considerations, and coordination with facility safety programs to address potential exposure risks. Our certified technicians hold HAZMAT certifications and follow strict safety protocols when working in industrial environments. We provide detailed cleaning documentation that supports facility maintenance programs and regulatory compliance requirements specific to industrial operations.

Root Intrusion Removal and Prevention

Root removal requires ongoing maintenance programs because roots continue growing and seeking moisture sources within sewer systems. We develop preventive cleaning schedules that address root growth patterns while recommending complementary treatments that discourage future intrusion. Our technicians identify pipe vulnerabilities during cleaning operations and provide recommendations for permanent solutions that prevent recurring root problems.

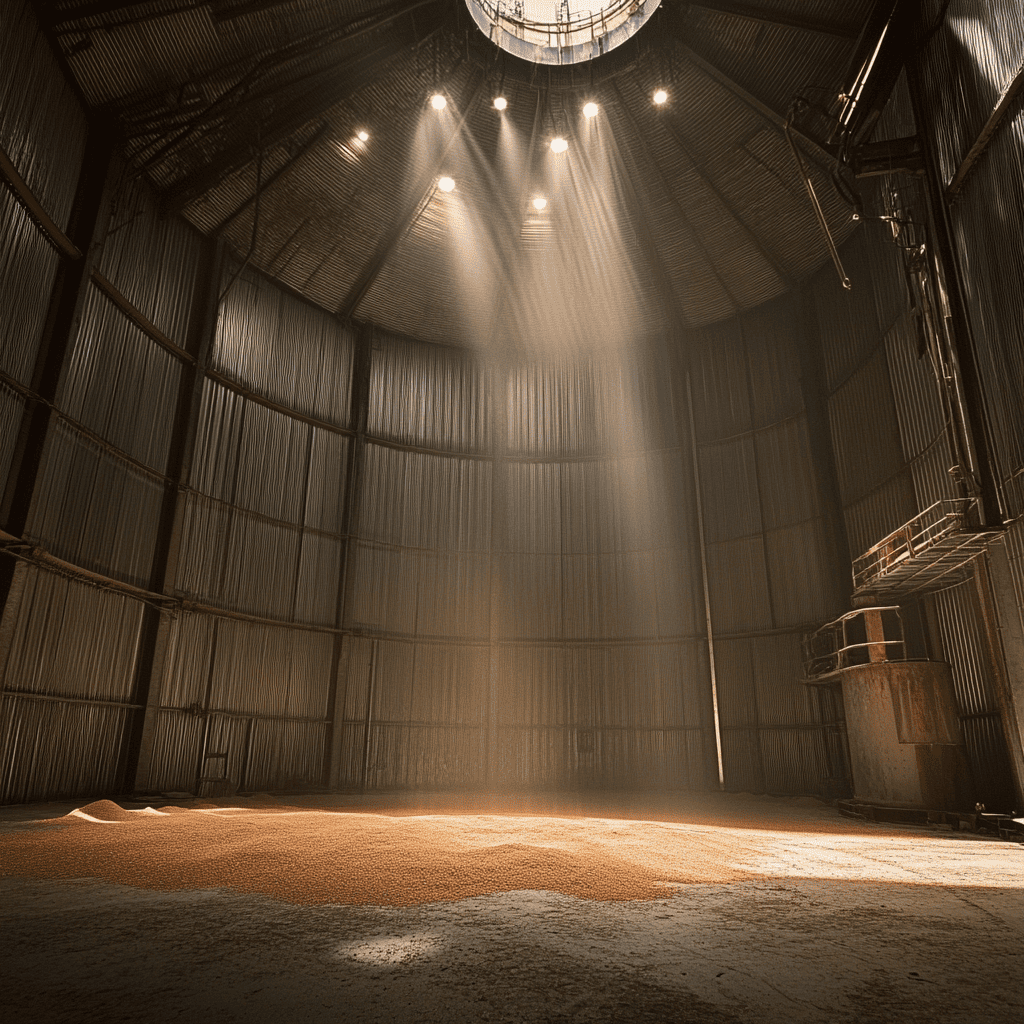

Grease and Oil Removal from Drain Systems

Grease removal requires specialized equipment configurations that maintain optimal water temperatures while providing sufficient pressure for effective cleaning action. Our technicians utilize temperature-controlled jetting systems that soften grease deposits while providing mechanical action to break up accumulations and flush debris from pipe systems. We coordinate grease removal with proper waste disposal procedures that meet environmental protection requirements.

Trust Tierra Environmental for All Your Cleaning Needs

Benefits of Professional Hydro Jetting Services

Complete Pipe Cleaning Versus Temporary Solutions

Complete pipe cleaning addresses the underlying causes of blockage problems rather than treating symptoms, providing sustainable solutions that maintain system performance over extended periods. Our hydro jetting services remove decades of accumulated buildup in single cleaning operations, restoring pipes to near-original capacity and flow characteristics. This thorough approach eliminates the cycle of temporary fixes that characterize conventional cleaning methods.

Environmentally Safe Cleaning Without Harsh Chemicals

Environmental safety considerations make hydro jetting ideal for applications near sensitive water sources, residential areas, and facilities with strict environmental compliance requirements. Our cleaning process generates no toxic byproducts while effectively addressing the most challenging blockage situations. This environmental responsibility supports sustainable maintenance practices while protecting community water resources and environmental quality.

Cost-Effective Long-Term Maintenance Solution

Preventive hydro jetting programs provide predictable maintenance costs while preventing expensive emergency repairs caused by severe blockages and system failures. Regular cleaning maintains system capacity and prevents damage to pipes, pumps, and associated equipment that occurs when blockages force systems to operate under pressure. These preventive benefits protect infrastructure investments while maintaining operational reliability.

Diagnostic Capabilities During Cleaning Operations

Inspection during cleaning operations reveals pipe damage, corrosion patterns, and joint deterioration that might not be apparent during standard inspections. Our technicians document these findings with detailed reports and photographic evidence that support maintenance planning and regulatory compliance requirements. This comprehensive approach provides maximum value from each service call while supporting long-term system management objectives.

Signs Your System Needs Professional Hydro Jetting

Recurring Blockages Despite Regular Maintenance

Recurring blockages often worsen over time as debris accumulation reduces effective pipe diameter and creates conditions that accelerate further buildup. Professional hydro jetting breaks this cycle by completely removing accumulated materials and restoring full pipe capacity. This thorough cleaning approach eliminates the conditions that cause rapid re-blocking and reduces maintenance frequency requirements.

Slow Drainage and Reduced Flow Capacity

Reduced flow capacity affects system efficiency and may indicate approaching failure conditions that could result in backups and operational disruptions. Early intervention with hydro jetting prevents these problems while restoring system performance to design specifications. This proactive approach prevents emergencies while maintaining optimal operational efficiency.

Unusual Odors from Drain Systems

Odor problems may indicate health and safety concerns, particularly in food service and healthcare facilities where sanitary conditions are required. Professional hydro jetting eliminates odor sources while restoring sanitary conditions that meet health department requirements. This thorough cleaning approach addresses both symptom relief and the underlying causes of odor problems.

Backup Events and System Overflows

Emergency backup situations often indicate long-term maintenance neglect that allows blockages to develop beyond conventional cleaning capabilities. Our emergency hydro jetting services restore immediate system function while providing recommendations for preventive maintenance programs that prevent recurring problems. This comprehensive approach addresses both immediate needs and long-term system reliability requirements.

The Science Behind High-Pressure Water Cleaning

Pressure Dynamics and Cleaning Effectiveness

Water pressure creates multiple cleaning actions, including direct impact force, scouring action from high-velocity water flow, and hydraulic shock waves that dislodge stubborn deposits. Different nozzle configurations modify these pressure dynamics to create specific cleaning patterns optimized for various blockage types and pipe conditions. This technical understanding allows our technicians to select optimal pressure settings for maximum effectiveness.

Flow Rate Considerations for Different Applications

Flow rate selection affects cleaning effectiveness and operational efficiency, with properly matched flow and pressure combinations providing optimal results while minimizing water usage and operational costs. Our equipment provides precise flow control that allows real-time adjustments based on cleaning progress and changing conditions. This technical capability maximizes cleaning effectiveness while maintaining operational efficiency.

Nozzle Design and Water Pattern Creation

Nozzle selection requires technical expertise to match cleaning patterns with specific blockage types and pipe conditions. Our technicians maintain extensive nozzle inventories that address diverse cleaning applications from delicate sensor cleaning to aggressive industrial blockage removal. This technical capability ensures optimal cleaning results while protecting system integrity and operational requirements.

Safety Protocols and Environmental Protection

Operator Safety and Equipment Handling

Equipment safety features include pressure relief systems, emergency shutoffs, and protective guards that prevent accidental injury during operation and maintenance activities. Our technicians conduct pre-operation safety inspections that verify proper equipment function and safety system operation before beginning cleaning activities. These safety protocols protect personnel while ensuring reliable equipment performance throughout cleaning operations.

Environmental Protection During Cleaning Operations

Wastewater and debris removal requires specialized handling procedures that address potential contamination and disposal requirements based on material characteristics and local regulations. Our technicians coordinate with waste management facilities that accept various waste types while providing proper documentation for regulatory compliance. This environmental responsibility protects community resources while meeting client obligations for proper waste management.

Site Protection and Access Management

Access management includes coordination with facility security, utility location services, and emergency responders to prevent conflicts and maintain safety throughout cleaning operations. Our procedures include communication protocols that keep facility management informed of progress, any discovered problems, and completion status. This professional approach minimizes operational disruption while maintaining safety and security requirements.

Trust Tierra Environmental for All Your Cleaning Needs

Preventive Maintenance and System Optimization

Developing Effective Cleaning Schedules

Seasonal variations in waste generation, weather patterns, and operational intensity affect optimal cleaning schedules for many facilities. Our maintenance programs account for these variations with flexible scheduling that intensifies cleaning during high-risk periods while extending intervals during lower-risk times. This adaptive approach maintains system reliability while optimizing maintenance costs and resource utilization.

System Monitoring and Performance Assessment

Performance assessment includes measurement of flow capacity, pressure testing, and visual inspection that documents system condition and remaining service life. Our technicians maintain detailed records that track system performance trends and identify patterns that indicate changing maintenance requirements. This data-driven approach supports informed decisions about cleaning schedules, system upgrades, and replacement planning.

Integration with Overall Facility Maintenance Programs

Integration considerations include coordination with other contractors, utility services, and regulatory compliance activities that affect facility operations. Our flexible scheduling accommodates these requirements while maintaining cleaning effectiveness and system reliability. This collaborative approach supports overall facility management objectives while providing specialized cleaning expertise.

Emergency Response and Rapid Problem Resolution

24/7 Emergency Service Availability

Emergency service coordination includes rapid assessment of problem severity, resource mobilization, and communication with facility management throughout response activities. Our emergency technicians carry comprehensive equipment inventories that address most emergency situations without requiring additional mobilization delays. This rapid response capability minimizes emergency duration while preventing secondary damage and operational disruption.

Rapid Assessment and Problem Resolution

Problem resolution focuses on immediate system restoration while identifying long-term solutions that prevent recurring emergencies. Our emergency services include temporary repairs, bypass installation, and rapid cleaning that restores basic system function while permanent solutions are planned and implemented. This comprehensive approach addresses both immediate needs and long-term system reliability requirements.

Trust Tierra Environmental for Professional Hydro Jetting Services

Our commitment to safety, environmental protection, and customer satisfaction drives every aspect of our hydro jetting services from initial assessment through final system restoration. We maintain comprehensive insurance coverage, safety certifications, and environmental compliance programs that protect our clients while delivering reliable cleaning results that maintain system performance and regulatory compliance.

Trust Tierra Environmental for All Your Cleaning Needs

Frequently Asked Questions

How often should commercial systems receive hydro jetting services?

- High-volume food service: Every 6-12 months for grease-impacted lines

- Manufacturing facilities: Annual cleaning for process waste systems

- Municipal storm sewers: Every 2-3 years or after major weather events

- Root-prone areas: Annual cleaning to prevent severe intrusions

- Industrial applications: Schedule based on waste characteristics and discharge volume

What pipe materials and sizes can be safely cleaned with hydro jetting?

Compatible Materials:

- Cast iron, steel, and ductile iron piping systems

- PVC, ABS, and other plastic pipe installations

- Clay tile and concrete pipe systems

- Most commercial and industrial piping materials

Special Considerations:

- Older pipe systems require pressure adjustment based on condition assessment.

- Damaged pipes may need repair before aggressive cleaning

Can hydro jetting damage pipes or system components?

Protection Measures:

- Pre-cleaning camera inspection identifies potential problem areas

- Variable pressure control allows adjustment for different pipe conditions

- Experienced technicians select appropriate nozzles and techniques

- Real-time monitoring prevents excessive pressure application

Risk Factors:

- Severely deteriorated pipes may require gentle cleaning approaches

- Improper pressure selection by inexperienced operators can cause damage

- Inadequate system assessment may miss vulnerable areas

How does hydro jetting compare to traditional drain cleaning methods?

Hydro Jetting Advantages:

- Removes all debris and completely cleans pipe walls

- Longer-lasting results with extended service intervals

- Chemical-free process with environmental safety

- Diagnostic capabilities during cleaning operations

- Addresses root intrusions and heavy blockages effectively

Traditional Method Limitations:

- Mechanical augers only punch holes through blockages

- Chemical cleaners provide temporary results, with environmental concerns

- Conventional methods cannot remove pipe wall accumulations

- Limited effectiveness against root intrusions and grease deposits

What emergencies require immediate hydro jetting services?

Immediate Threats:

- Sewage backups threaten health and property safety

- Complete system blockages preventing normal operations

- Storm sewer failures during weather events

- Industrial process disruptions from blocked discharge lines

Urgent Situations:

- Severe flow restrictions affecting operations

- Health department violations requiring immediate correction

- Environmental discharge problems with regulatory implications

Do you provide documentation and compliance reporting?

Service Documentation:

- Before-and-after camera inspection reports with photographic evidence

- Cleaning pressure logs and equipment settings used

- Waste removal volumes and disposal certification

- System condition assessment and maintenance recommendations

Compliance Support:

- Environmental discharge compliance verification

- Municipal permit requirement documentation

- Insurance and regulatory inspection support

- Maintenance program documentation for asset management

Can you coordinate with other facility maintenance activities?

Coordination Services:

- Integration with planned maintenance shutdowns and utility work

- Scheduling around operational requirements and peak periods

- Coordination with other contractors and service providers

- Emergency response during planned maintenance activities

Planning Support:

- Long-term maintenance schedule development

- Capital improvement project coordination

- System upgrade planning and implementation support

- Preventive maintenance program development