Hydro Blasting

Hydro Blasting Services - Tierra Environmental

Powerful Industrial Cleaning Solutions for Over Two Decades

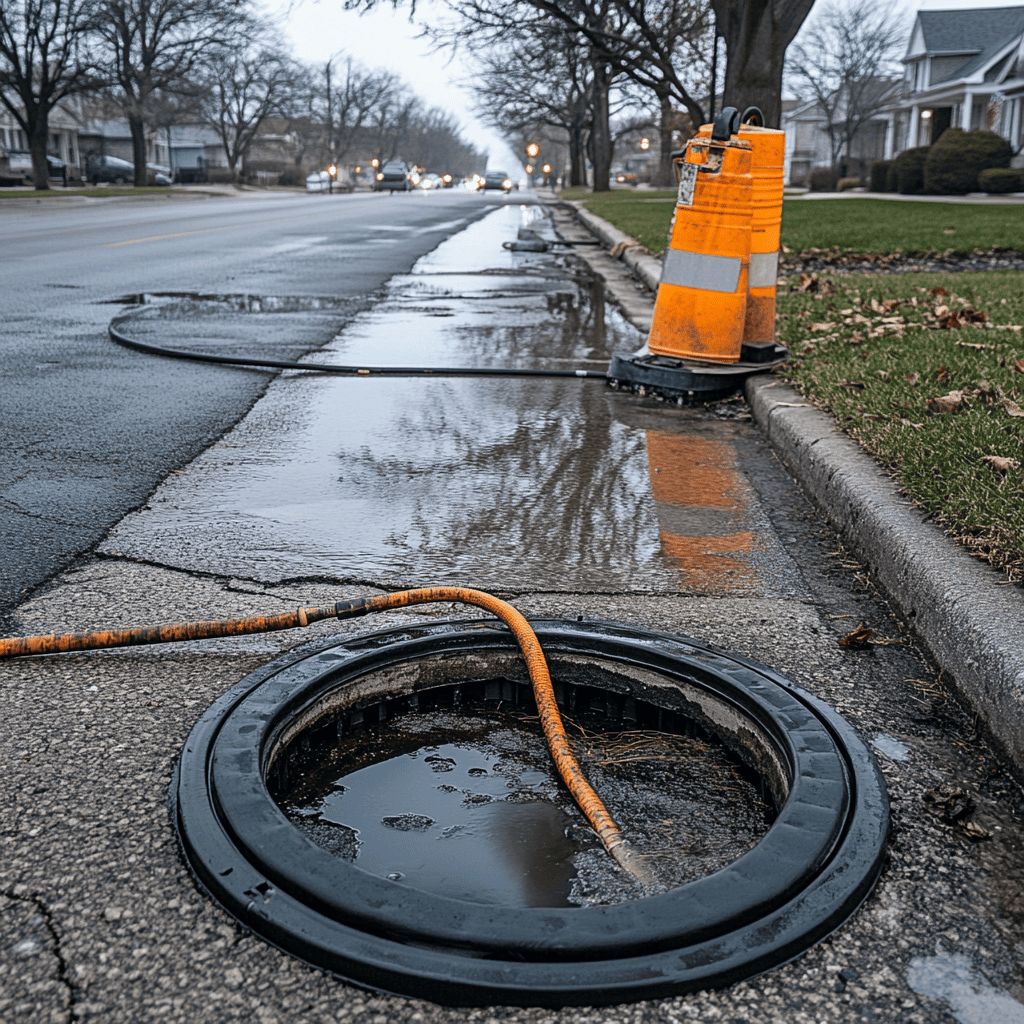

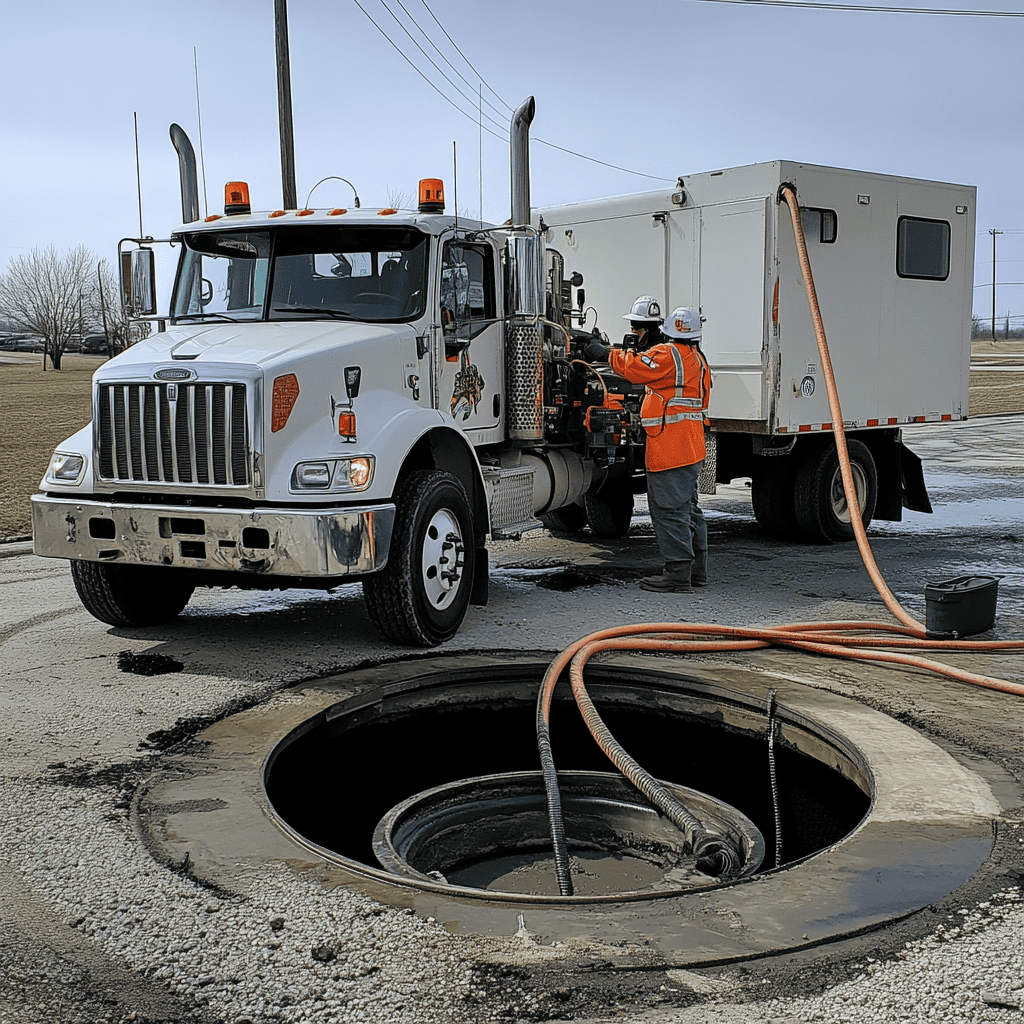

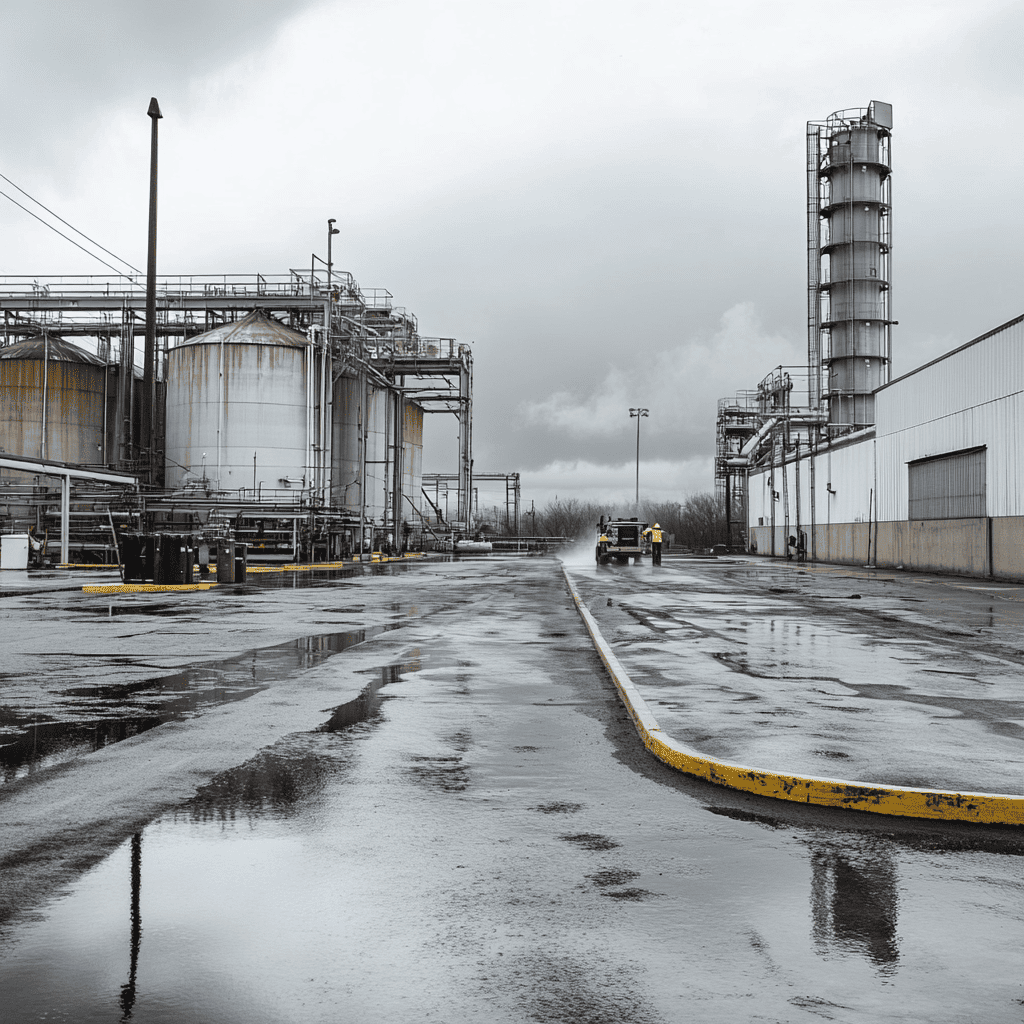

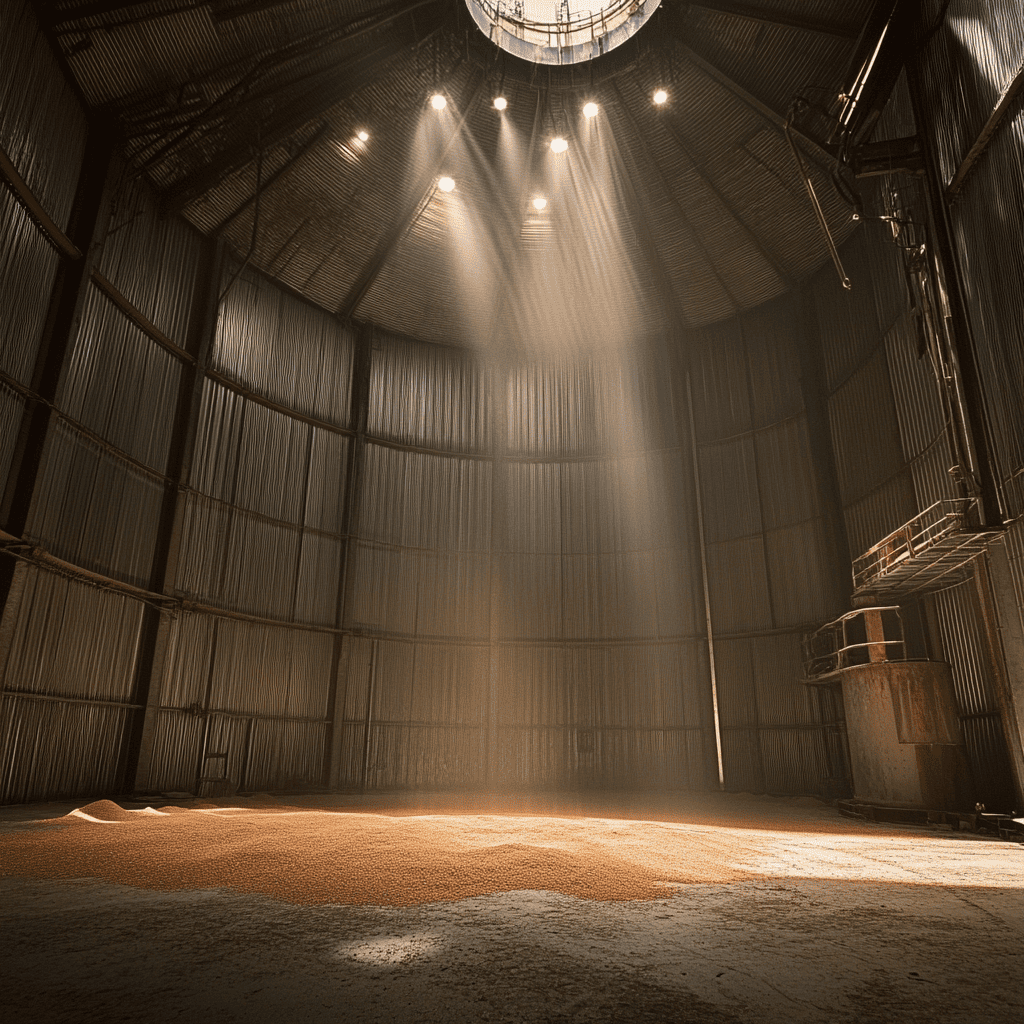

Tierra Environmental Services delivers professional hydro blasting services throughout Indiana and the surrounding Midwest region, providing powerful high-pressure water cleaning solutions for industrial facilities, manufacturing plants, and commercial operations. Our certified technicians utilize advanced hydroblasting equipment to remove stubborn deposits, scale, and contaminants from tanks, vessels, heat exchangers, and processing equipment. With specialized training in high-pressure operations and confined space entry, our team safely handles complex cleaning projects that restore equipment performance while maintaining strict safety protocols.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

What Is Hydro Blasting and Why Industrial Facilities Need It

Industrial facilities require hydro blasting services to maintain equipment efficiency, prevent corrosion damage, and meet regulatory compliance standards. Heat exchangers fouled with mineral deposits lose thermal efficiency, increasing energy costs and reducing production capacity. Storage tanks with accumulated sediments and scale can develop corrosion problems that compromise structural integrity and product quality. Regular hydro blasting maintenance prevents these issues while extending equipment lifespan and maintaining operational performance.

Our Hydro Blasting Services Include:

Tank and Vessel Cleaning

Heat Exchanger Cleaning

Pipe and Tube Cleaning

Surface Preparation and Coating Removal

Equipment Decontamination

Trust Tierra Environmental for All Your Cleaning Needs

Industries We Serve with Hydro Blasting Services

Food and Beverage Manufacturing

Chemical and Petrochemical Processing

Power Generation and Utilities

Manufacturing and Processing

Pulp and Paper Industry

Hydro Blasting Equipment and Pressure Capabilities

High-Pressure Pump Systems

Specialized Nozzle Configurations

Water Recovery and Filtration Systems

Safety and Monitoring Equipment

Safety Protocols for High-Pressure Operations

Personnel Training and Certification

Pre-Operation Safety Assessment

Pressure Testing and Equipment Inspection

Environmental and Containment Measures

Environmental Benefits and Compliance

Chemical-Free Cleaning Process

Waste Minimization and Recovery

Regulatory Compliance Support

Trust Tierra Environmental for All Your Cleaning Needs

Project Planning and Execution

Site Assessment and Method Selection

Scheduling and Coordination

Progress Monitoring and Quality Control

Final Inspection and Documentation

Maintenance Programs and Service Scheduling

Preventive Cleaning Programs

Emergency Response Services

Turnaround and Shutdown Support

Cost-Effective Industrial Cleaning Solutions

Efficiency Restoration and Energy Savings

Equipment Life Extension

Maintenance Cost Reduction

Quality Assurance and Service Standards

Experienced Technical Team

Advanced Equipment and Technology

Comprehensive Documentation

Trust Tierra Environmental for Professional Hydro Blasting

Our commitment to safety, environmental protection, and service excellence makes us the trusted partner for facilities requiring high-quality hydro blasting services. We understand the operational demands of industrial facilities and work diligently to provide cleaning solutions that minimize downtime while maximizing results.

Trust Tierra Environmental for All Your Cleaning Needs

Frequently Asked Questions

What pressure levels are used for different hydro blasting applications?

- Light cleaning and surface preparation: 5,000-15,000 PSI for removing loose deposits and preparing surfaces

- Medium-duty cleaning: 15,000-25,000 PSI for scale removal and equipment cleaning

- Heavy-duty applications: 25,000-40,000 PSI for removing stubborn deposits and hardened materials

- Delicate equipment: Lower pressures with specialized techniques to prevent damage

How does hydro blasting compare to chemical cleaning methods?

Environmental Benefits:

- No chemical storage, handling, or disposal requirements

- Eliminates chemical exposure risks for workers

- Reduces environmental impact and regulatory compliance burden

- Water-only process supports sustainability goals

Effectiveness:

- Removes deposits that chemicals cannot dissolve

- Provides immediate visual confirmation of cleaning results

- Works on all deposit types without chemical compatibility concerns

- Achieves consistent results regardless of chemical resistance

Safety and Cost:

- Eliminates chemical exposure hazards

- Reduces waste disposal costs and regulatory requirements

- Provides faster cleaning with immediate results

- Eliminates chemical purchase and storage costs

What safety measures are required for hydro blasting operations?

Personnel Requirements:

- OSHA-certified technicians with high-pressure training

- Specialized personal protective equipment, including face shields and cut-resistant clothing

- Confined space entry certification for tank and vessel cleaning

- Emergency response training and first aid certification

Equipment Safety:

- Pressure testing and inspection before each use

- Emergency shutdown systems and pressure monitoring

- Proper hose routing and securing to prevent whipping

- Safety barriers and work area isolation

Site Safety:

- Comprehensive hazard assessment and safety planning

- Electrical lockout and hazard isolation

- Environmental protection and containment measures

- Coordination with facility safety personnel

Can hydro blasting damage equipment or surfaces?

Damage Prevention:

- Proper pressure selection based on substrate materials

- Appropriate nozzle distance and angle maintenance

- Graduated pressure increase to test surface response

- Specialized techniques for sensitive equipment

Material Compatibility:

- Safe for most metals, concrete, and industrial materials

- Effective on hardened deposits without substrate damage

- Suitable for heat exchanger tubes and vessel surfaces

- Appropriate for both thick and thin-walled equipment

Professional Expertise:

- Experienced technicians recognize material limitations

- Proper equipment selection prevents damage

- Quality control monitoring ensures safe operations

- Insurance coverage protects against unlikely damage scenarios

How long do hydro blasting projects typically take?

Small Equipment Cleaning: 4-8 hours for individual tanks or heat exchangers.

Medium Projects: 1-3 days for multiple vessels or complex equipment.

Large Turnaround Support: 1-2 weeks for comprehensive facility cleaning.

Emergency Response: 2-6 hours for urgent cleaning needs

Factors Affecting Duration:

- Deposit thickness and characteristics

- Equipment size and complexity

- Access conditions and safety requirements

- Coordination with facility operations

What happens to the removed materials and wastewater?

Water Management:

- Recovery systems capture and filter cleaning water

- Filtered water can be reused for additional cleaning

- Final discharge meets environmental standards

- Documentation provides audit trails for compliance

Removed Materials:

- Characterization determines appropriate disposal methods

- Hazardous materials are handled according to regulations

- Non-hazardous materials are recycled when possible

- Disposal certificates provided for record-keeping

Environmental Protection:

- Containment prevents environmental contamination

- Proper handling minimizes waste generation

- Recycling opportunities reduce disposal costs

- Compliance with all applicable regulations

Do you provide emergency hydro blasting services?

Response Time: Typically mobilized within 4-6 hours of notification.

Equipment Availability: Fully equipped service vehicles are ready for immediate deployment.

Service Area: Emergency coverage throughout our Midwest service region.

24/7 Availability: Emergency contact system ensures rapid response

Emergency Situations:

- Equipment failures requiring immediate cleaning

- Production disruptions from fouling problems

- Regulatory compliance issues require prompt action

- Safety hazards from accumulated deposits

Can you work around production schedules and operating constraints?

Scheduling Flexibility:

- Night and weekend operations to minimize production impact

- Coordination with maintenance windows and shutdowns

- Staged cleaning to maintain partial operations

- Emergency response capabilities for urgent needs

Operational Coordination:

- Planning meetings with facility personnel

- Safety coordination with plant operations

- Equipment isolation and preparation support

- Progress updates throughout cleaning operations

Minimal Disruption:

- Efficient cleaning techniques reduce service duration.

- Proper planning minimizes operational interference

- Emergency preparedness prevents unexpected delays

- Professional coordination supports smooth operations