Rail Cart Cleaning

Rail Cart Cleaning Services | Tierra Environmental

Specialized Railroad Equipment Maintenance for Over Two Decades

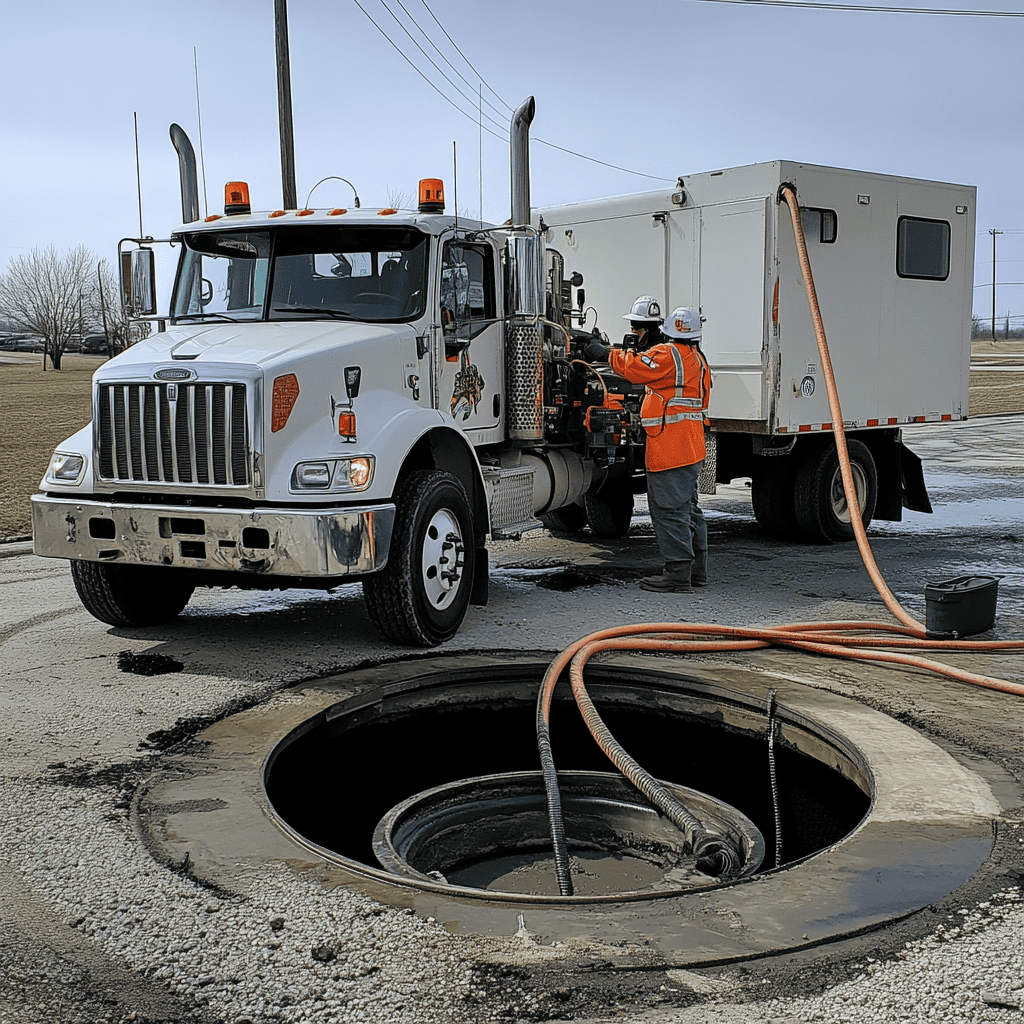

Tierra Environmental Services delivers professional rail cart cleaning throughout Indiana and the broader Midwest region, supporting railroad companies, freight operators, and industrial facilities that depend on clean, compliant rolling stock. Our certified technicians specialize in removing accumulated materials, hazardous residues, and contamination from all types of rail cars, including tank cars, hopper cars, and specialized transport equipment. With our railroad equipment maintenance solutions, operators can maintain safety standards, regulatory compliance, and operational efficiency while extending equipment life and protecting cargo integrity.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

Why Professional Rail Cart Cleaning Is Required for Railroad Operations

Our Rail Cart Cleaning Services Include:

Tank Car Interior Cleaning and Decontamination

Hopper Car and Open-Top Cleaning

Hazardous Material Residue Removal

Regulatory Compliance Documentation

Equipment Inspection and Maintenance Support

Trust Tierra Environmental for All Your Cleaning Needs

Benefits of Professional Rail Cart Cleaning

Prevents Cross-Contamination and Cargo Quality Issues

Maintains Federal Transportation Compliance

Extends Equipment Life and Reduces Maintenance Costs

Protects Worker Safety and Environmental Compliance

Supports Operational Efficiency and Customer Satisfaction

Understanding Rail Cart Contamination and Cleaning Requirements

Types of Rail Car Contamination and Their Impacts

Environmental contamination from weather exposure, rail yard operations, and transportation conditions adds additional cleaning challenges. Dust, dirt, and atmospheric pollutants accumulate on equipment surfaces, while moisture can promote bacterial growth and corrosion in areas where organic materials are present. Understanding these contamination types helps operators appreciate why professional cleaning services are necessary for maintaining equipment quality and regulatory compliance.

Federal Regulations Governing Rail Car Cleanliness

Food and Drug Administration regulations apply to rail cars transporting food-grade materials, requiring sanitization procedures that meet strict purity standards. These requirements include approved cleaning agents, specific procedures for different commodity types, and documentation that demonstrates compliance with food safety regulations. Professional cleaning services help operators navigate these complex requirements while maintaining the documentation necessary for regulatory compliance.

Cargo-Specific Cleaning Requirements

Petroleum products leave residues that require specific cleaning procedures to prevent fire hazards and environmental contamination while preparing equipment for different cargo types. Each commodity category has unique cleaning requirements that professional service providers understand and implement to maintain compliance and cargo quality. This specialized knowledge protects operators from costly mistakes while maintaining equipment standards.

Rail Car Types and Specialized Cleaning Approaches

Tank Car Cleaning for Liquid Cargo Applications

External cleaning addresses environmental contamination while inspecting protective coatings and structural components for maintenance needs. Tank car cleaning often requires confined space entry procedures and specialized safety equipment to protect workers from exposure to residual vapors or hazardous atmospheres. Professional technicians trained in these procedures maintain safety while achieving thorough cleaning results that meet regulatory and customer requirements.

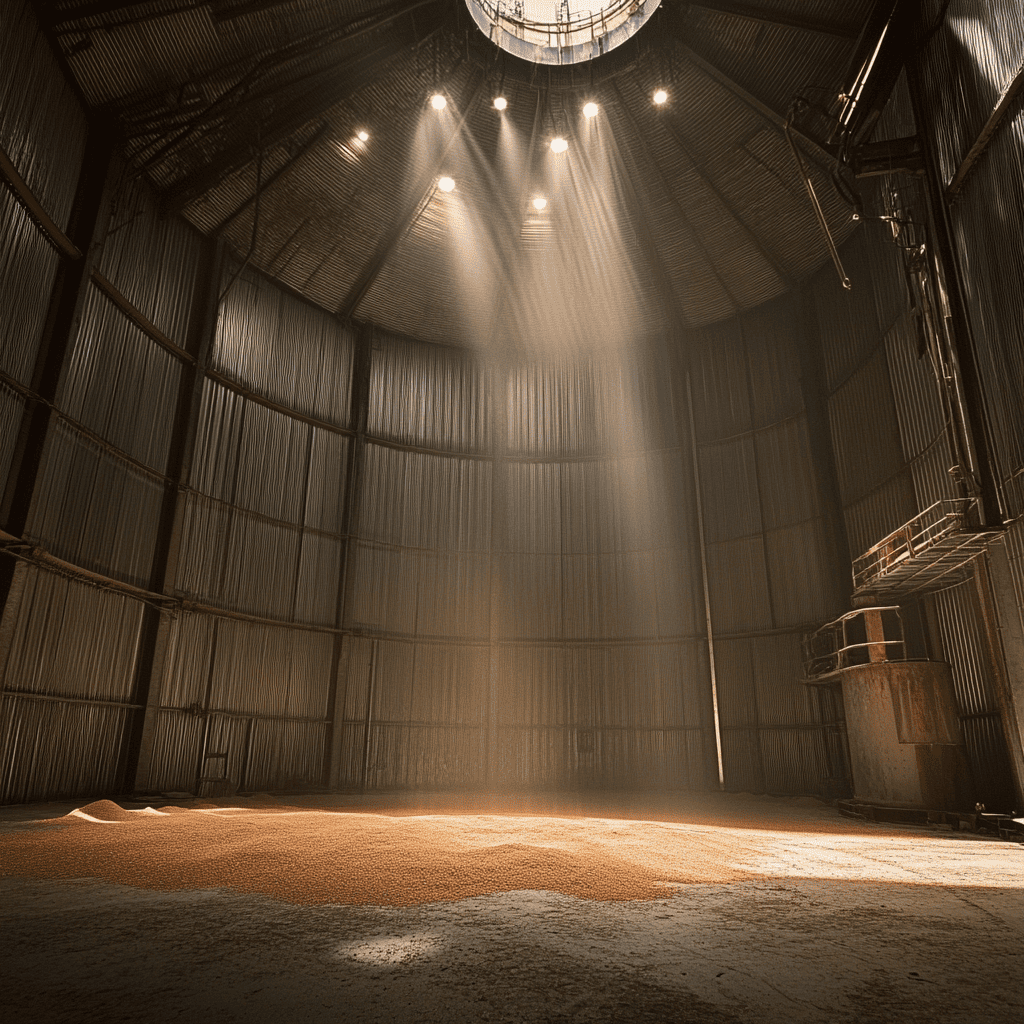

Hopper Car and Bulk Cargo Container Cleaning

Food-grade hopper cars require additional sanitization procedures that eliminate bacteria and pests while meeting strict cleanliness standards for edible commodities. This cleaning process includes the treatment of all surfaces that will contact with food products while preventing contamination that could affect consumer safety. Professional cleaning maintains these standards while providing documentation that satisfies customer and regulatory requirements.

Specialized Equipment for Unique Cargo Types

Military and government cargo applications often have specific security and cleaning requirements that must be maintained throughout the service process. Professional cleaning services with appropriate certifications and security clearances handle these specialized requirements while maintaining the confidentiality and security protocols required for sensitive applications.

Safety Protocols for Rail Cart Cleaning Operations

Hazardous Material Handling and Worker Protection

Confined space entry procedures are required for many rail car cleaning operations, particularly tank cars and covered hoppers, where atmospheric hazards can accumulate. Our technicians are trained in confined space safety protocols, including atmospheric monitoring, ventilation requirements, and emergency rescue procedures. This training protects workers while maintaining the safety standards required for insurance coverage and regulatory compliance.

Environmental Protection and Waste Management

Waste characterization and proper disposal facility selection require expertise in environmental regulations and waste management procedures. Our team handles all aspects of waste management, from initial characterization through final disposal, while providing documentation that demonstrates proper environmental stewardship. This comprehensive approach protects clients from environmental liability while supporting sustainable business practices.

Emergency Response and Incident Management

Incident documentation and reporting procedures meet regulatory requirements while protecting clients from liability exposure. Our emergency response capabilities include coordination with local emergency services, regulatory agencies, and client management to address incidents professionally and completely. This preparedness minimizes incident impacts while maintaining the safety and environmental protection standards required for continued operations.

Trust Tierra Environmental for All Your Cleaning Needs

Equipment and Technology for Professional Rail Car Cleaning

Specialized Cleaning Equipment and Systems

Vacuum systems for waste removal and atmospheric control maintain safe working conditions while efficiently removing cleaning waste and accumulated materials. Our equipment fleet includes specialized tools for accessing confined spaces, handling hazardous materials, and maintaining the containment necessary for environmental protection. This equipment capability supports thorough cleaning while maintaining the safety and efficiency standards required for professional service.

Quality Control and Inspection Technology

Photographic documentation and detailed inspection reports provide permanent records of cleaning results and equipment condition. This documentation supports regulatory compliance, insurance requirements, and customer quality specifications while providing evidence of professional service completion. Our quality control procedures maintain consistent service standards while protecting clients from liability exposure related to inadequate cleaning.

Documentation and Compliance Management Systems

Digital documentation systems improve efficiency while providing secure storage and easy retrieval of service records. Our systems integrate cleaning documentation with regulatory requirements and customer specifications to provide comprehensive records that support all compliance needs. This technological approach improves service quality while reducing administrative burden for clients and service providers alike.

Industry Applications and Customer Types

Railroad Companies and Freight Operators

Regional and short-line railroads often require flexible service arrangements that accommodate smaller fleets and specialized equipment types. We provide customized service programs that meet the unique needs of smaller operators while maintaining the same quality standards applied to major railroad operations. This flexibility supports all types of railroad operations regardless of size or specialization.

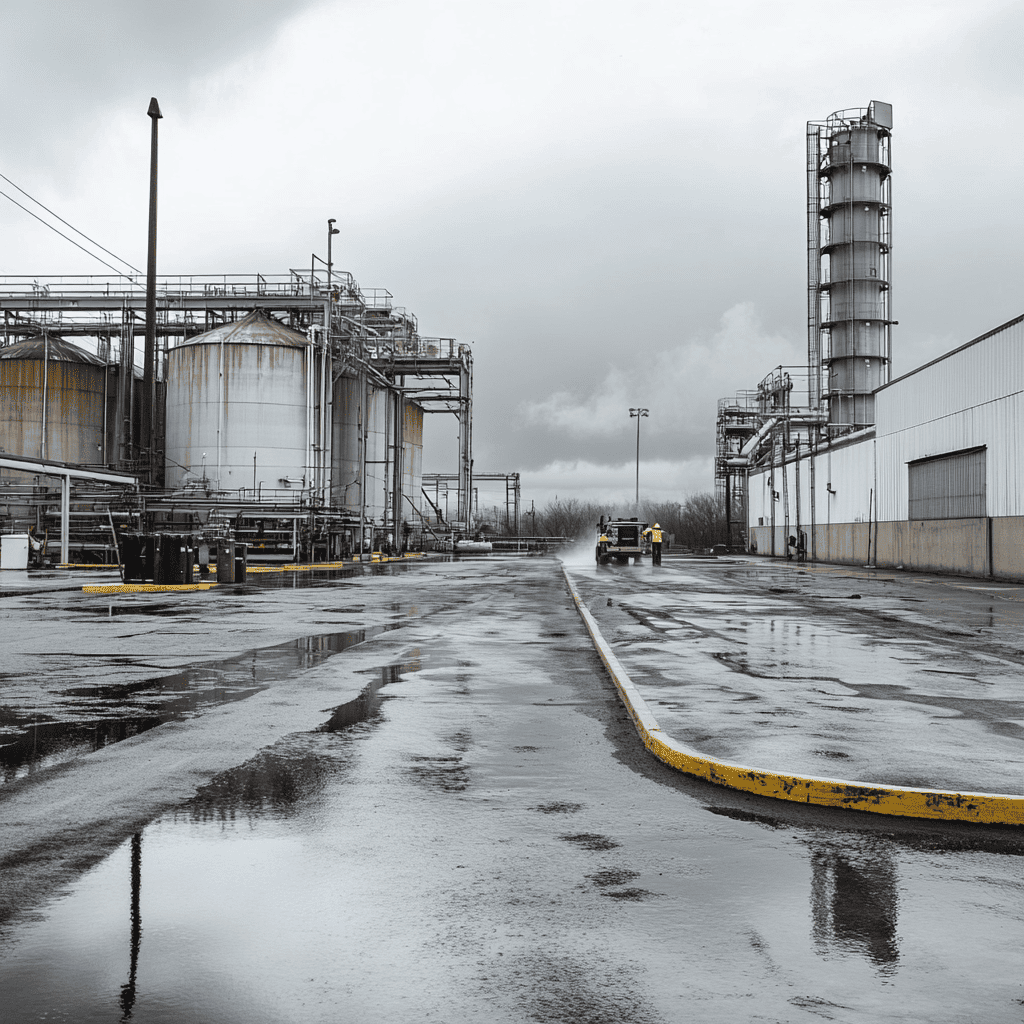

Chemical and Petroleum Industry Applications

Food-grade chemical applications require additional quality standards that prevent contamination while maintaining the purity necessary for food and pharmaceutical applications. We provide specialized cleaning procedures that meet these strict requirements while maintaining documentation that satisfies customer and regulatory specifications. This capability supports the specialized needs of chemical companies serving food and pharmaceutical markets.

Agricultural and Food Industry Services

Food processing companies often require specialized cleaning procedures that meet FDA regulations for food contact surfaces while maintaining the sanitary conditions necessary for consumer product safety. We provide cleaning and sanitization services that meet these strict requirements while maintaining documentation that supports food safety audits and regulatory inspections.

Preventive Maintenance and Equipment Care

Regular Cleaning Schedules and Maintenance Programs

Customized maintenance schedules consider equipment usage patterns, cargo types, and regulatory requirements to optimize service frequency while minimizing costs. Our maintenance planning services help operators develop programs that balance cost control with equipment condition and compliance requirements. This planning capability supports efficient operations while maintaining the equipment standards necessary for continued service.

Equipment Condition Monitoring and Reporting

Detailed condition reports support maintenance planning and budgeting while providing documentation for insurance and regulatory requirements. Our reporting systems track equipment condition over time while identifying trends that help predict maintenance needs and optimize replacement schedules. This information supports informed decision-making while maintaining equipment reliability and compliance.

Component Replacement and Repair Coordination

Parts availability and repair scheduling coordination help minimize equipment downtime while maintaining cost control. We work with clients to plan maintenance activities during scheduled cleaning operations, reducing total service time while maintaining equipment availability for revenue service. This integrated approach improves operational efficiency while reducing total maintenance costs.

Trust Tierra Environmental for Professional Rail Cart Cleaning

Let our experienced team handle your rail car cleaning needs so you can focus on transportation operations and customer service. Our comprehensive services, safety expertise, and regulatory knowledge provide the support railroad operations need to maintain efficient equipment utilization while meeting all applicable safety and environmental requirements.

Trust Tierra Environmental for All Your Cleaning Needs

Frequently Asked Questions

What types of rail cars can you clean?

- Tank cars for liquid chemicals, petroleum products, and food-grade materials

- Hopper cars for bulk commodities like grain, coal, and industrial materials

- Covered hoppers for dry bulk materials requiring weather protection

- Gondola cars for scrap metal, construction materials, and bulk goods

- Specialized equipment, including cryogenic tanks and pressure vessels

- Military and government equipment with appropriate security clearances

Do you handle hazardous material decontamination?

- Chemical residue removal with appropriate neutralization procedures

- Radioactive material decontamination meeting NRC standards

- Petroleum product cleaning with fire safety protocols

- Toxic material removal with worker protection measures

- Corrosive substance neutralization and safe disposal

What documentation do you provide after rail car cleaning?

- Before-and-after inspection reports with photographic evidence

- Cleaning procedure documentation specifying methods and materials used

- Waste disposal certificates confirming proper environmental handling

- Regulatory compliance verification meeting DOT and EPA requirements

- Equipment condition reports identifying maintenance needs

- Quality certifications suitable for customer and regulatory inspections

How long does rail car cleaning typically take?

- Tank cars: 4-8 hours, depending on cargo type and contamination level

- Hopper cars: 2-6 hours based on material type and accumulation

- Hazardous material decontamination: 6-12 hours with additional safety procedures

- Multiple car projects: Coordinated scheduling for efficiency

Can you coordinate with the railroad scheduling requirements?

- Scheduled maintenance windows coordinated with operational needs

- Multi-location service following equipment movement schedules

- Emergency response for urgent cleaning requirements

- Flexible scheduling accommodating operational priorities

- Documentation delivery meeting the railroad administrative requirements

What safety certifications do your technicians hold?

- OSHA 10 and OSHA 30 for general safety awareness and training

- HAZMAT certification for hazardous material handling procedures

- Confined space entry training for tank car and enclosed equipment cleaning

- Respiratory protection certification for atmospheric hazard protection

- Emergency response training for incident management and worker safety

Do you provide emergency rail car cleaning services?

- Contamination incidents requiring immediate decontamination

- Regulatory compliance issues needing rapid resolution

- Equipment failures causing contamination or safety hazards

- Cargo quality problems requiring immediate cleaning intervention

- Environmental spills needing professional cleanup and documentation