Grease trap pumping

Professional Grease Trap Pumping Services - Tierra Environmental

Expert Grease Trap Pumping Services Throughout the Illinois Region

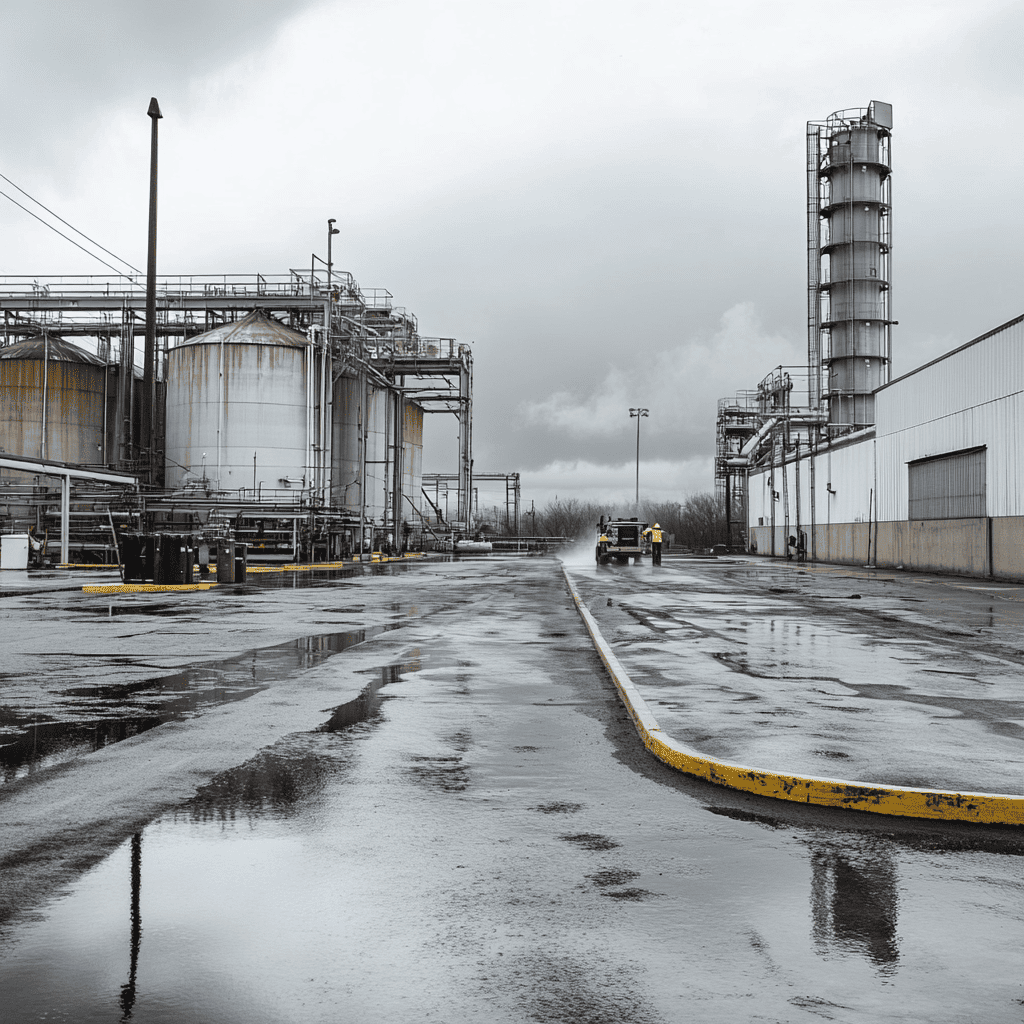

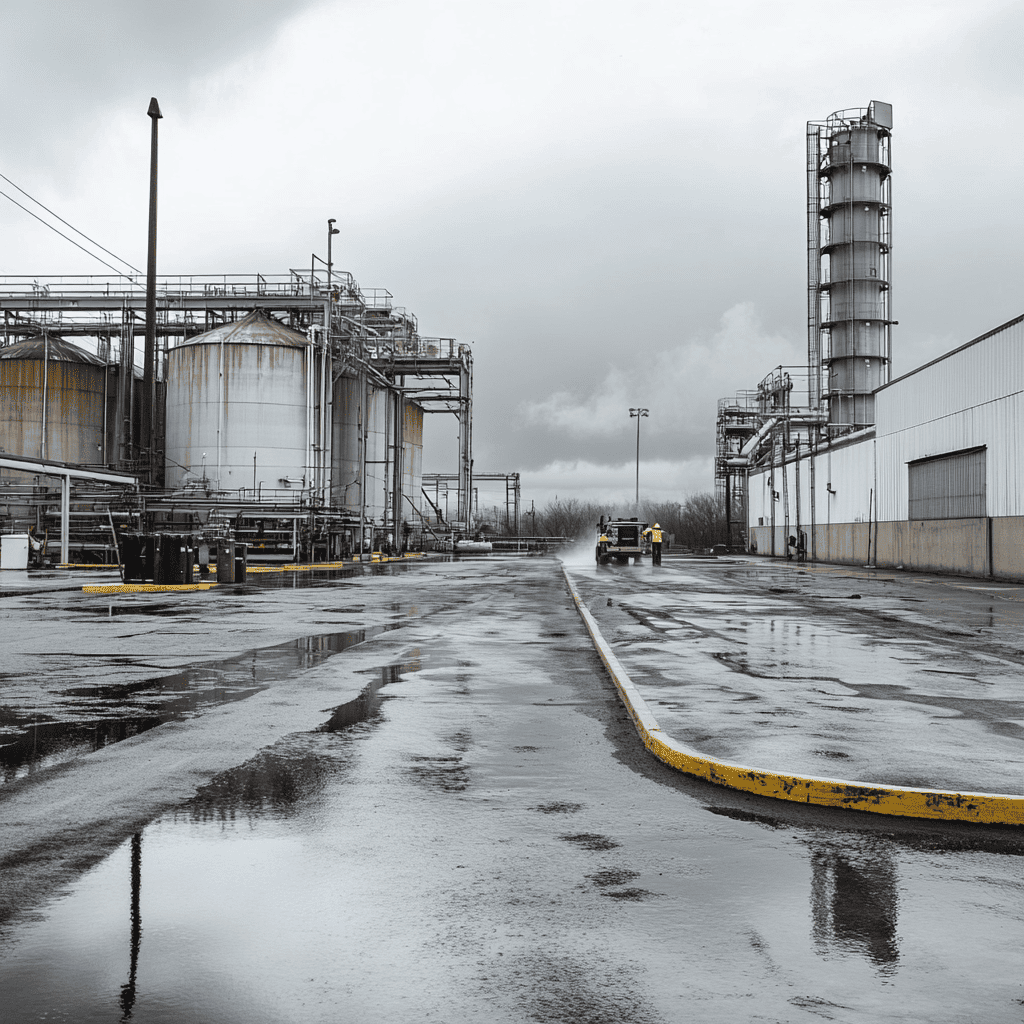

Tierra Environmental Services delivers professional grease trap pumping solutions for restaurants, commercial kitchens, and food service facilities throughout Illinois and surrounding areas. Our certified technicians specialize in complete waste removal from grease interceptor systems, eliminating accumulated fats, oils, and grease (FOG) that can cause system failures, regulatory violations, and operational disruptions. With over two decades of experience in commercial waste management, we provide reliable pumping services that keep your grease management systems functioning properly while maintaining full compliance with local health and environmental regulations.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

Why Regular Grease Trap Pumping Protects

Your Business Operations

Our Complete Grease Trap Pumping Services

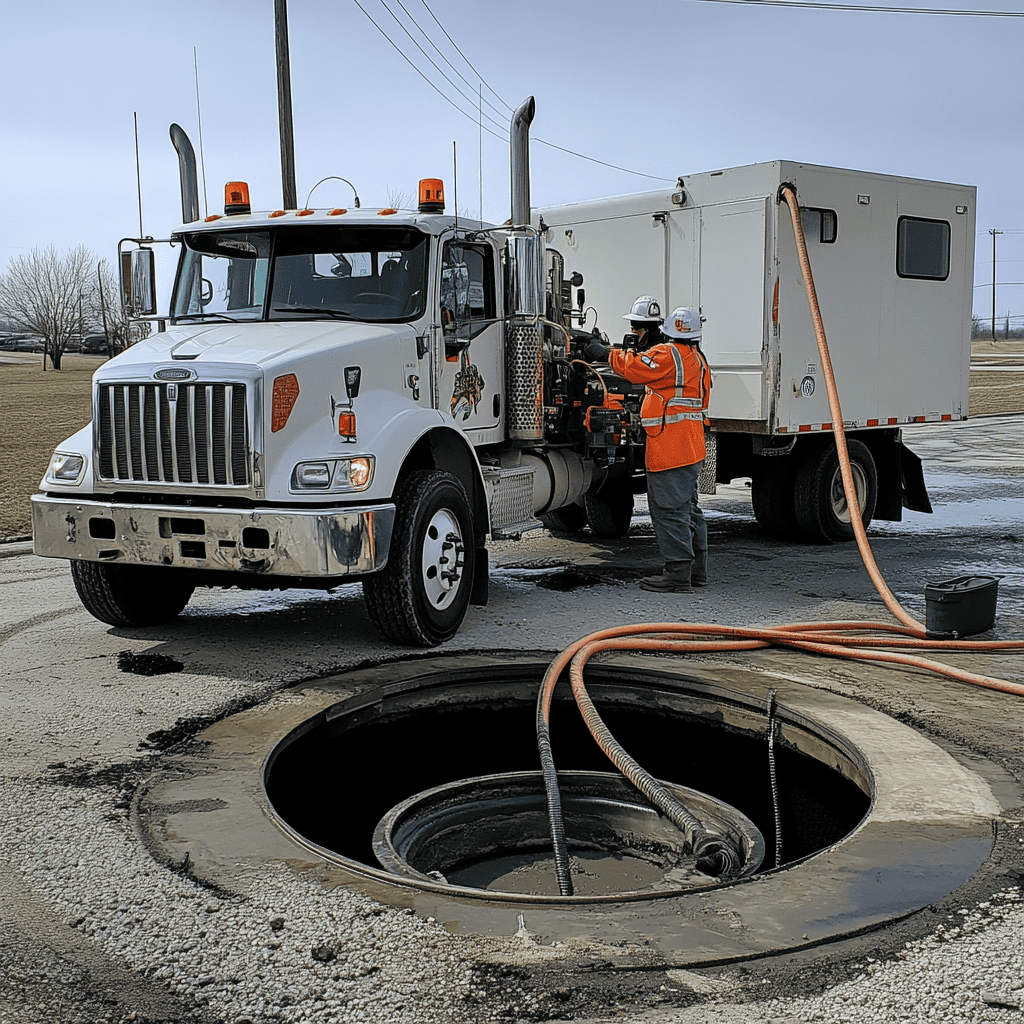

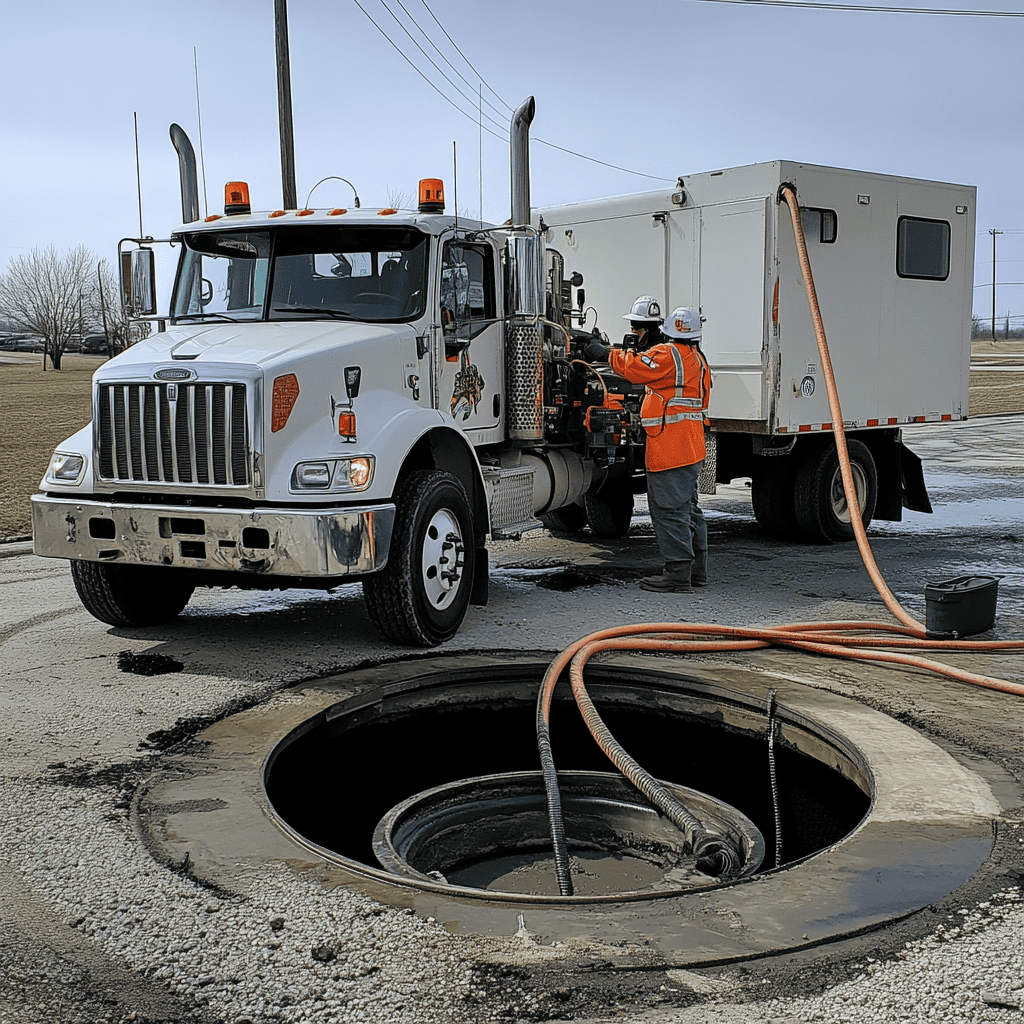

Total Waste Extraction and System Emptying

Multi-Layer Waste Separation and Removal

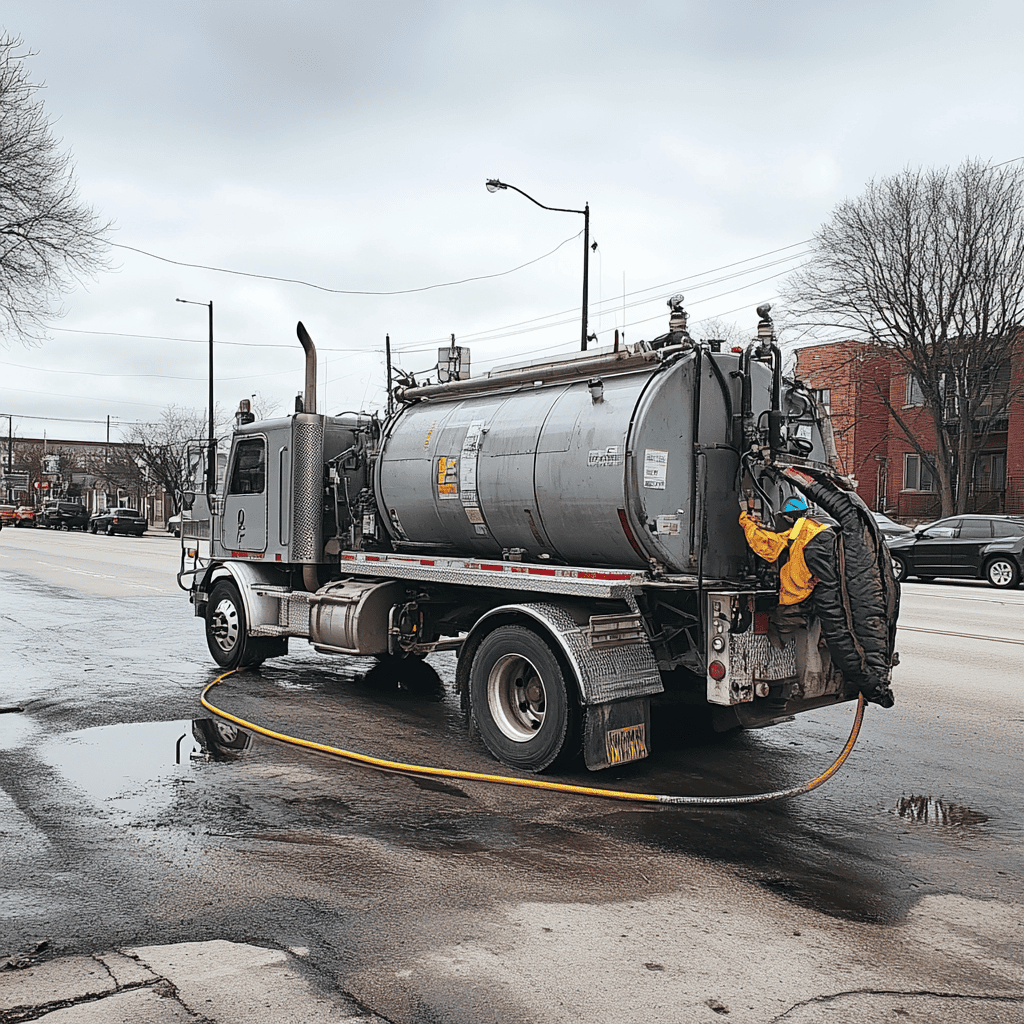

High-Capacity Vacuum Truck Operations

Immediate System Assessment and Problem Identification

Regulatory Compliance Documentation

Trust Tierra Environmental for All Your Cleaning Needs

Understanding Grease Trap Pumping Frequency Requirements

Volume-Based Pumping Schedules

Seasonal Variations and Business Cycles

Kitchen Operations and Menu Impact

Professional Pumping Equipment and Waste Handling

Specialized Vacuum Truck Technology

Safe Waste Transportation and Disposal

Spill Prevention and Site Protection

Health Department and Environmental Compliance

Local Health Code Requirements

Municipal Discharge Regulations

Environmental Protection Standards

Emergency Pumping Services and Rapid Response

24/7 Emergency Availability

Overflow Prevention and Damage Control

Critical Inspection Response

Protect Your Operations, Contact Us Today

Preventive Maintenance and System Protection

Proactive Pumping Programs

System Monitoring and Performance Tracking

Integration with Cleaning Services

Cost Management and Service Value

Predictable Maintenance Costs

Insurance and Liability Protection

Regulatory Penalty Avoidance

Service Area Coverage and Response Capabilities

Primary Midwest Service Region

Extended Service Capabilities

Mobile Service Fleet

Why Choose Tierra Environmental for Grease Trap Pumping

Two Decades of Professional Experience

Since 2000, Tierra Environmental Services has provided reliable grease trap pumping services for commercial establishments throughout the Midwest. Our experience includes work with restaurants, food processing facilities, institutional kitchens, and municipal facilities, giving us the knowledge to handle diverse pumping requirements effectively. This experience helps us anticipate problems and provide solutions that keep systems operating efficiently.

Certified Technicians and Safety Standards

Our pumping technicians hold OSHA 10, OSHA 30, and HAZMAT certifications that demonstrate professional competency in waste handling and safety procedures. These certifications reflect our commitment to safe operations while meeting industry standards for professional service. Certified technicians provide reliable service while protecting your facility from liability associated with improper waste handling.

Comprehensive Waste Management Solutions

Beyond pumping services, we provide complete grease management solutions including cleaning, repairs, compliance support, and emergency response. This comprehensive approach allows businesses to work with a single provider for all grease trap maintenance needs while receiving coordinated services that maximize system performance and regulatory compliance.

Frequently Asked Questions About Grease Trap Pumping

How often should grease traps be pumped?

- High-volume operations: Monthly pumping is typically required.

- Medium-volume establishments: Every 6-8 weeks, maintains compliance.

- Lower-volume facilities: Quarterly pumping may be sufficient.

- Heavy grease generators: More frequent service needed.

- Regulatory requirements: Some jurisdictions mandate specific schedules

What's the difference between pumping and cleaning?

Pumping services:

- Sewer backups and property damage from overflowing traps

- Health code violations that can force immediate business closure

- Offensive odors from anaerobic bacterial growth

- Equipment damage from grease backups into kitchen systems

- Environmental violations with significant fines and penalties

- Insurance claim denials for inadequate maintenance

Cleaning services:

- Remove stubborn residues from trap walls and baffles

- Sanitize surfaces and eliminate odor-causing bacteria

- Address the buildup that pumping cannot remove

- Often performed in combination with pumping

Can pumping be delayed if the trap doesn't appear full?

- Waste continues accumulating, reducing the separation efficiency

- Anaerobic conditions develop, producing offensive odors

- Solids settle and harden, making future pumping more difficult

- Regulatory violations may occur even if the trap appears functional

- Emergency situations become more likely as capacity decreases

What happens to waste removed during pumping?

Waste processing:

- Transportation to permitted disposal facilities

- Separation of recyclable grease materials

- Treatment of contaminated water components

- Proper disposal of non-recyclable materials

Environmental benefits:

- Grease recycling into biodiesel and other products

- Prevention of sewer system contamination

- Protection of water treatment facilities

- Compliance with environmental regulations

Do you provide emergency pumping services?

Environmental benefits:

- Grease trap overflows and backups

- Failed health inspections requiring immediate correction

- System malfunctions are preventing normal operations

- Urgent compliance issues threatening business closure

How much does grease trap pumping cost?

Cost factors:

- Trap size and waste volume

- Service frequency and scheduling

- Location and accessibility

- Emergency vs. scheduled service

- Additional services required

Value considerations:

- Prevents expensive emergency repairs

- Maintains regulatory compliance

- Avoids business closure penalties

- Protects equipment investment

- Reduces insurance liability exposure

What safety measures are followed during pumping?

Safety procedures:

- OSHA-certified technicians with proper training

- Specialized safety equipment and protective gear

- Site containment and spill prevention measures

- Proper ventilation and gas monitoring

- Emergency response equipment on every vehicle

Site protection:

- Traffic control and work area barriers

- Containment systems for spill prevention

- Property protection during operations

- Coordination with facility management

- Cleanup procedures for any incidents

Can you coordinate pumping with other maintenance services?

Coordinated services:

- Pumping and cleaning schedule integration

- Repair and maintenance coordination

- Compliance reporting and documentation

- Emergency response across all services

- Single-source management for all grease trap needs

Do you service grease traps outside of Indiana?

Schedule Your Grease Trap Pumping Service Today

Call us now to establish a pumping schedule that fits your business needs and operational requirements. Let our professional team handle your grease trap maintenance so you can focus on serving customers and growing your business in the competitive food service industry.