Industrial Cleaning

Industrial Cleaning Services - Tierra Environmental

Specialized Manufacturing Facility Maintenance Solutions for Over Two Decades

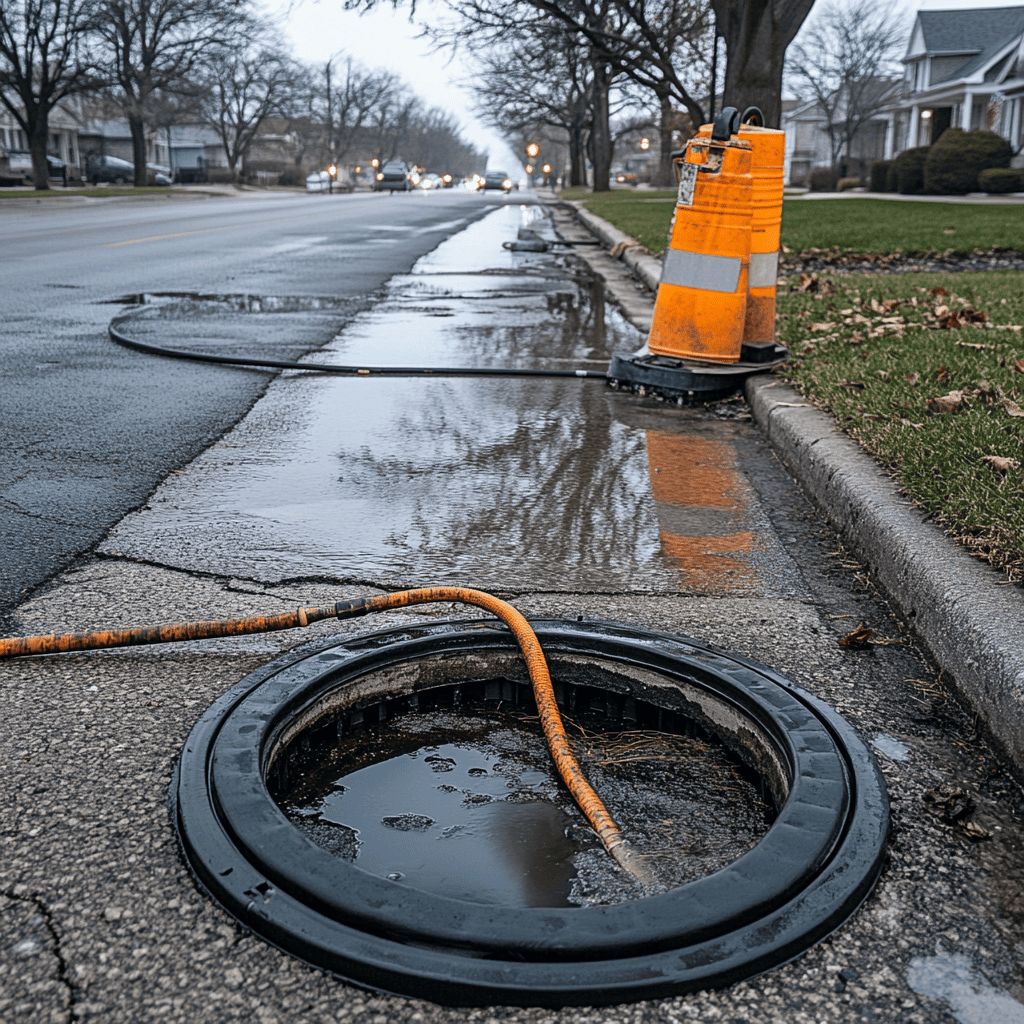

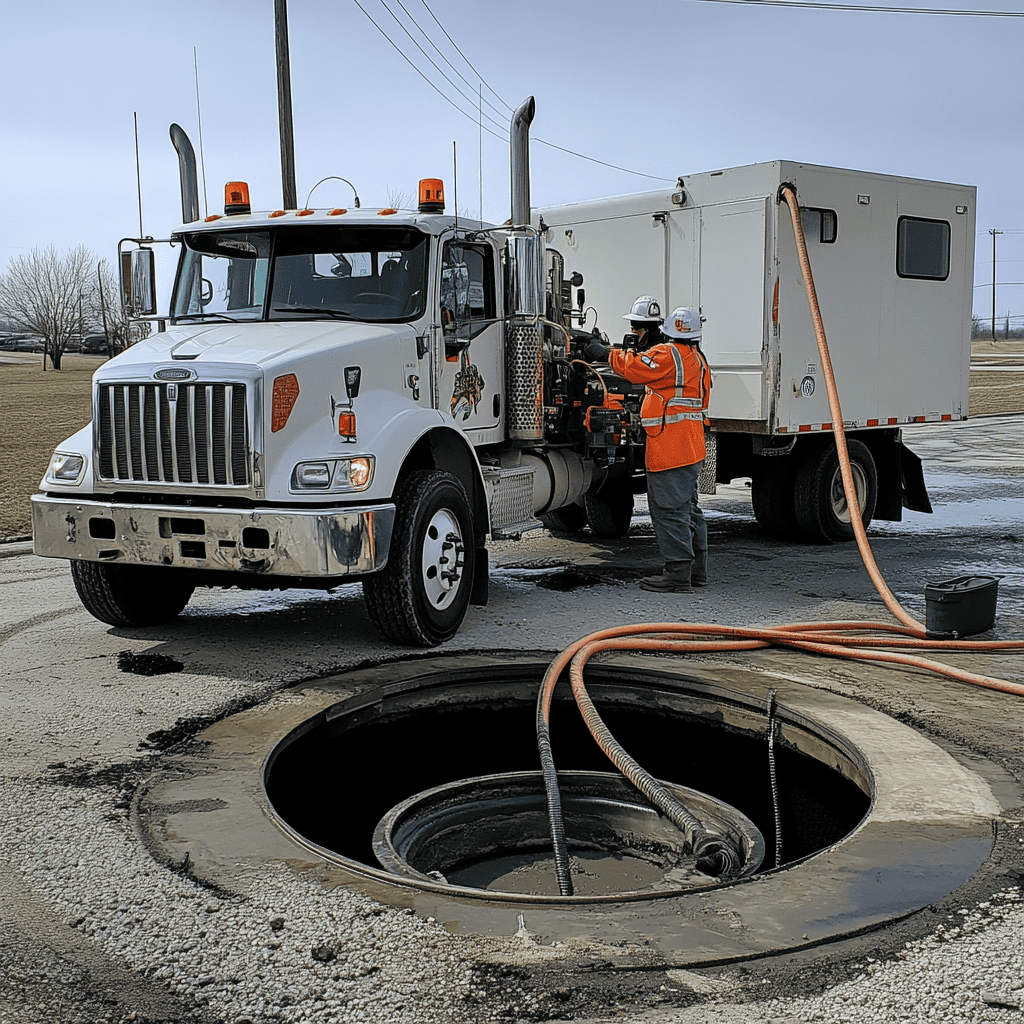

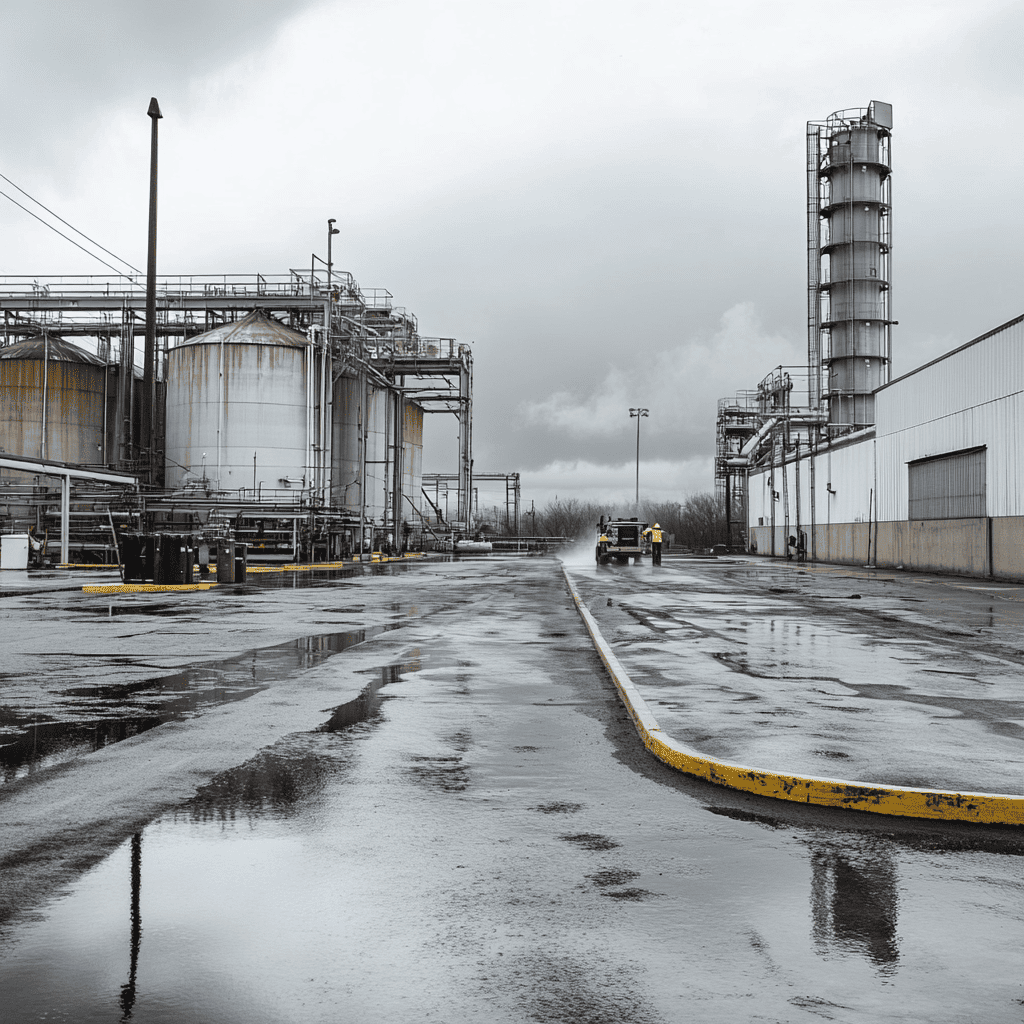

Tierra Environmental Services delivers professional industrial cleaning throughout Indiana and the broader Midwest region, serving manufacturing facilities, processing plants, warehouses, and heavy industrial operations that require specialized maintenance solutions. Our certified technicians provide thorough facility cleaning that addresses the unique challenges of industrial environments, from equipment decontamination to confined space cleaning and hazardous material removal. With our reliable industrial maintenance programs, facility managers can maintain safe working conditions, regulatory compliance, and operational efficiency while focusing on core production activities.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

Why Professional Industrial Cleaning Is Required for Manufacturing Operations

Manufacturing operations must maintain clean environments to protect product quality, worker health, and equipment reliability while meeting strict regulatory standards for workplace safety and environmental protection. Professional industrial cleaning eliminates contaminants, reduces safety risks, and maintains the sanitary conditions necessary for efficient production operations and regulatory compliance.

Our Industrial Cleaning Services Include:

Manufacturing Equipment Cleaning and Decontamination

Equipment decontamination services address chemical residues, biological contaminants, and hazardous materials that accumulate during normal production operations. Our technicians use proper safety protocols and specialized cleaning agents to eliminate contaminants while protecting sensitive equipment components from damage. This decontamination process maintains safe working conditions while extending equipment life and reliability.

Facility Deep Cleaning and Maintenance

Deep cleaning services include ceiling cleaning, wall washing, floor treatments, and structural cleaning that addresses hard-to-reach areas where contaminants accumulate. Our technicians use appropriate cleaning methods for different surface materials while protecting sensitive equipment and maintaining production schedules. This detailed cleaning maintains facility appearance while supporting safety and quality objectives.

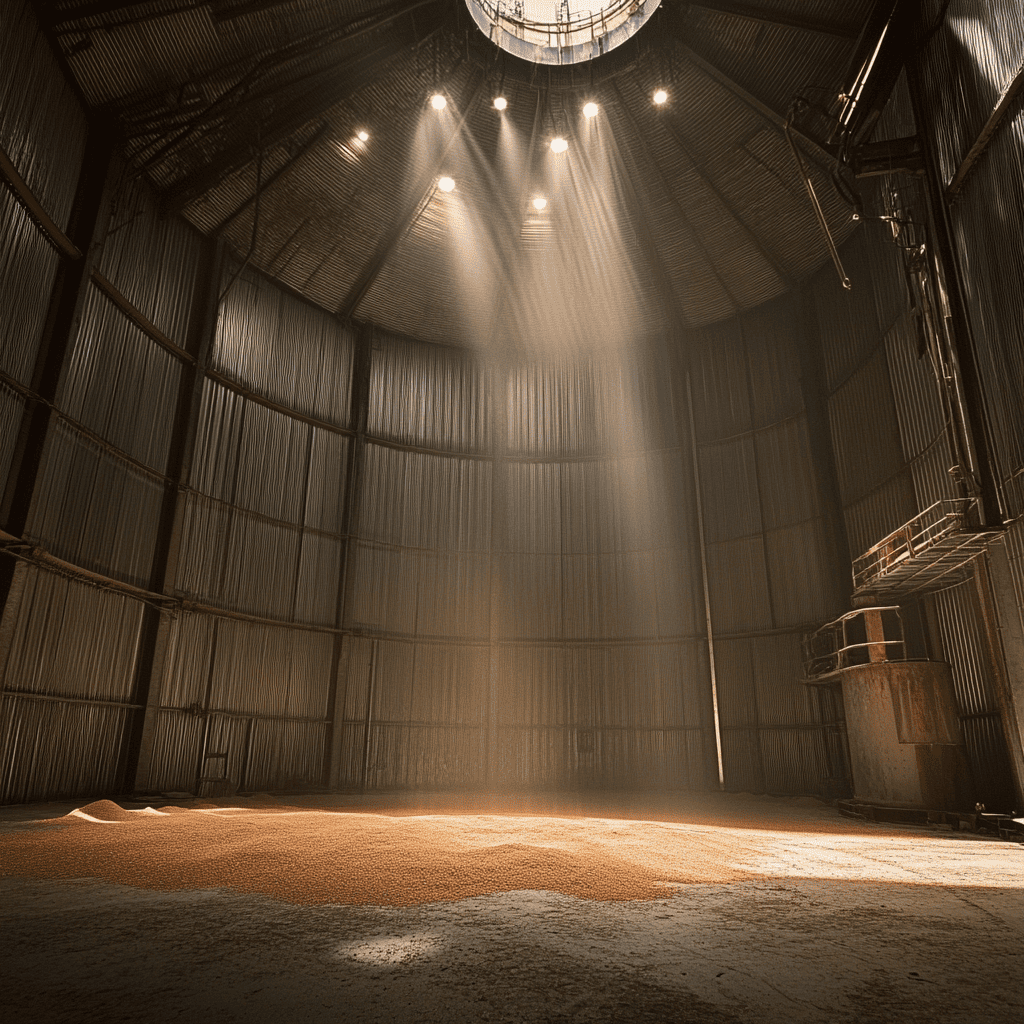

Tank and Vessel Cleaning

We clean various tank types, including chemical storage tanks, food processing vessels, water treatment systems, and specialized industrial containers. Our cleaning processes address specific residue types while using appropriate cleaning agents and disposal methods for different applications. This specialized approach protects tank surfaces while maintaining the cleanliness standards required for continued use.

High-Pressure Washing and Surface Preparation

Surface preparation services include the removal of old coatings, rust, scale, and other materials that interfere with new applications or equipment performance. Our technicians use appropriate preparation methods for different materials while containing debris and managing waste disposal. This preparation work supports maintenance activities while maintaining clean facility conditions.

Hazardous Material Cleanup and Disposal

Hazardous waste disposal services include proper characterization, packaging, and transportation of regulated materials to appropriate disposal facilities. We handle various waste types, including chemicals, oils, solvents, and contaminated materials, according to environmental regulations. This complete waste management approach protects facilities from liability while maintaining regulatory compliance.

Trust Tierra Environmental for All Your Cleaning Needs

Benefits of Professional Industrial Cleaning

Maintains Product Quality and Prevents Contamination

Regular professional cleaning maintains the clean manufacturing environments required for sensitive products, including food processing, pharmaceuticals, and electronics manufacturing. These industries require specific cleanliness standards that only professional cleaning can achieve and maintain consistently. Professional services protect product integrity while supporting quality certification requirements.

Reduces Equipment Downtime and Maintenance Costs

Clean equipment operates more efficiently, consuming less energy and requiring fewer repairs than equipment compromised by contamination buildup. Professional cleaning maintains equipment performance while identifying potential problems before they cause failures. This proactive maintenance approach reduces total operating costs while maximizing production reliability.

Protects Worker Safety and Health

Proper cleaning prevents the accumulation of materials that could create fire or explosion hazards in manufacturing environments. Our cleaning methods address various safety risks while maintaining the clean conditions required for safe operations. This hazard reduction protects both workers and facilities while supporting safety compliance objectives.

Supports Regulatory Compliance

Environmental regulations require proper handling and disposal of industrial waste materials that professional cleaning services manage according to applicable standards. Our waste management capabilities protect facilities from environmental violations while supporting sustainability objectives. This regulatory support allows facilities to focus on production while maintaining compliance obligations.

Understanding Industrial Cleaning Requirements

Types of Industrial Contaminants and Cleaning Challenges

Chemical contaminants may require neutralization or special handling procedures to prevent hazardous reactions during cleaning operations. Biological contaminants need sanitization protocols that eliminate pathogens while maintaining food safety or pharmaceutical standards. Professional cleaning services understand these requirements while implementing appropriate protocols for each contamination type.

Safety Considerations in Industrial Cleaning

Confined space cleaning requires specific certifications, safety equipment, and entry procedures that protect workers from atmospheric hazards, entrapment, and other dangers. Our technicians maintain confined space certifications while using proper safety protocols for tank and vessel cleaning. This specialized training allows safe access to areas that facility personnel cannot clean effectively.

Equipment and Technology Requirements

Advanced cleaning technologies, including automated systems, robotic cleaners, and specialized chemical formulation, improve cleaning effectiveness while reducing safety risks and labor requirements. Professional services stay current with technological advances while implementing new methods that improve cleaning results. This technology adoption provides clients with improved cleaning performance and cost-effectiveness.

Facility Assessment and Cleaning Program Development

Initial Facility Evaluation and Contamination Assessment

Contamination assessment includes sampling and analysis of residues, identification of hazardous materials, and evaluation of cleaning challenges that affect service planning. Understanding contamination types and sources allows the development of targeted cleaning strategies that address specific problems while preventing future accumulation. This scientific approach improves cleaning effectiveness while reducing costs and safety risks.

Customized Cleaning Protocol Development

Cleaning protocols include detailed procedures for equipment preparation, cleaning agent application, residue removal, and surface restoration that maintain consistent results between cleaning events. Written procedures provide clear guidance for cleaning personnel while supporting quality control and regulatory compliance. These documented protocols maintain cleaning standards while supporting continuous improvement efforts.

Scheduling and Production Coordination

Planned maintenance shutdowns provide opportunities for comprehensive cleaning that addresses accumulated contamination and performs deep cleaning of equipment and facilities. We coordinate with maintenance teams to maximize cleaning efficiency during these scheduled periods while supporting maintenance activities. This integrated approach optimizes both cleaning and maintenance outcomes.

Specialized Industrial Cleaning Applications

Food and Beverage Processing Facility Cleaning

Processing equipment cleaning includes removal of product residues, sanitization of food contact surfaces, and deep cleaning of areas where bacteria could accumulate. Our technicians understand food safety requirements while implementing cleaning protocols that maintain product integrity and consumer safety. This expertise protects food processors from safety incidents while maintaining quality standards.

Chemical and Pharmaceutical Manufacturing Cleaning

Cleanroom and controlled environment cleaning requires specific procedures, equipment, and documentation that maintain the sterile conditions required for pharmaceutical manufacturing. Our cleanroom cleaning services address particle control, contamination prevention, and validation support while maintaining the environmental conditions critical for product quality. This specialized cleaning supports pharmaceutical compliance while protecting product integrity.

Steel and Metal Processing Facility Maintenance

High-temperature equipment cleaning addresses scale and residue buildup that can affect product quality and equipment performance in metal processing operations. Our technicians use specialized techniques for cleaning furnaces, rolling mills, and processing equipment while maintaining safety protocols for high-temperature environments. This specialized cleaning maintains equipment performance while extending operational life.

Power Generation and Utility Cleaning

Cooling system cleaning addresses scale, biological growth, and chemical deposits that reduce efficiency and create maintenance problems in power generation systems. Our cooling system expertise includes both mechanical and chemical cleaning methods that restore system performance while maintaining water treatment effectiveness. This specialized cleaning optimizes system efficiency while reducing maintenance costs.

Trust Tierra Environmental for All Your Cleaning Needs

Quality Assurance and Performance Monitoring

Cleaning Effectiveness Verification

Advanced testing methods, including ATP monitoring, particle counting, and residue analysis, provide objective measurements of cleaning effectiveness that support quality certifications and regulatory compliance. These scientific methods verify cleaning performance while identifying areas for improvement in cleaning protocols. This data-driven approach optimizes cleaning effectiveness while reducing costs and improving reliability.

Documentation and Compliance Reporting

Compliance reporting includes summaries of cleaning activities, waste management, safety performance, and regulatory compliance that facility managers use for internal reporting and regulatory submissions. Our reporting system provides the information needed for environmental permits, safety audits, and quality certifications while supporting continuous improvement efforts. This reporting capability reduces administrative burden while maintaining compliance obligations.

Continuous Improvement and Program Optimization

Program optimization includes evaluation of cleaning frequencies, protocol effectiveness, and technology upgrades that improve cleaning performance while reducing environmental impact and operational costs. Our optimization process considers changing facility requirements, new technologies, and regulatory updates that affect cleaning programs. This adaptive approach maintains program effectiveness while supporting facility objectives.

Emergency Response and Specialized Services

Industrial Spill Response and Containment

Spill response services include hazard assessment, containment implementation, material recovery, and site remediation that restore normal operations while preventing environmental damage. Our response team maintains specialized equipment and training for various spill types while coordinating with regulatory agencies when required. This comprehensive response capability protects facilities from liability while minimizing business impact.

Confined Space Cleaning and Entry

Confined space cleaning includes atmospheric monitoring, ventilation systems, emergency rescue procedures, and specialized cleaning equipment designed for restricted access environments. Our safety protocols exceed regulatory requirements while maintaining the flexibility needed for various confined space configurations. This specialized capability addresses cleaning needs that other services cannot safely perform.

Shutdown and Turnaround Support

Turnaround cleaning includes equipment preparation for maintenance, facility deep cleaning, and post-maintenance cleanup that supports efficient shutdown execution while maintaining safety and quality standards. Our turnaround experience includes coordination with multiple contractors while maintaining safety protocols in complex work environments. This specialized support helps facilities achieve shutdown objectives while maintaining schedule and budget requirements.

Trust Tierra Environmental for Professional Industrial Cleaning

Our commitment to safety, quality, and regulatory compliance makes us the trusted partner for industrial facilities that require professional cleaning services. We understand the critical role that cleanliness plays in manufacturing operations while providing cost-effective solutions that support productivity, safety, and compliance objectives.

Trust Tierra Environmental for All Your Cleaning Needs

Frequently Asked Questions

What types of industrial facilities do you service?

- Manufacturing plants producing automotive, electronics, and consumer goods

- Food and beverage processing facilities require FDA compliance

- Chemical and pharmaceutical operations with strict contamination control

- Steel mills and metal processing facilities with specialized cleaning needs

- Power generation plants, including coal, gas, and renewable energy facilities

- Warehouses and distribution centers with large-scale cleaning requirements

- Paper mills and pulp processing facilities with unique contamination challenges

How do you handle hazardous materials during cleaning?

- Specialized equipment, including containment systems and safety monitoring devices

- Proper waste characterization and disposal through licensed facilities

- Safety protocols that exceed regulatory requirements for worker protection

- Emergency response capabilities for spill containment and cleanup

- Documentation that meets regulatory requirements for hazardous waste management

Can you work around our production schedules?

- 24/7 availability for emergency cleaning and scheduled maintenance

- Weekend and holiday service to minimize production disruption

- Shift coordination that works around your operating schedule

- Planned shutdown support that maximizes cleaning efficiency during maintenance periods

- Phased cleaning that allows continued operation in unaffected areas

- Rapid mobilization for urgent cleaning requirements

What safety certifications do your technicians maintain?

- OSHA 10 and OSHA 30 for general construction and industrial safety

- HAZMAT operations for hazardous material handling and emergency response

- Confined space entry for safe work in tanks, vessels, and restricted areas

- Respiratory protection for work in contaminated environments

- First aid and CPR for emergency medical response

- Fall protection for elevated work and safety line systems

How do you maintain product quality during cleaning operations?

- Contamination prevention protocols that prevent cross-contamination between products

- Approved cleaning agents that meet food safety, pharmaceutical, or industry-specific requirements

- Equipment protection during cleaning to prevent damage to sensitive components

- Environmental controls that maintain temperature, humidity, and cleanliness standards

- Validation procedures that verify cleaning effectiveness and product safety

- Documentation that supports quality certifications and regulatory compliance

What documentation do you provide for regulatory compliance?

- Service reports detailing cleaning activities, materials used, and results achieved

- Waste disposal records with proper manifests and disposal facility certificates

- Safety compliance verification, including confined space permits and HAZMAT documentation

- Quality verification data,a including cleaning effectiveness measurements and testing results

- Environmental compliance records for air emissions, waste discharge, and material handling

- Training records documenting technician qualifications and safety certifications

Do you provide emergency industrial cleaning services?

- 24/7 emergency response for spills, contamination incidents, and urgent cleaning needs

- Rapid mobilization with specialized equipment and trained personnel

- Spill containment and cleanup for chemical, oil, and hazardous material releases

- Contamination control to prevent the spread of biological or chemical contaminants

- Production support cleaning that minimizes downtime during equipment failures

- Regulatory coordination when emergencies require agency notification

How do you handle waste disposal from industrial cleaning?

- Waste characterization to determine proper handling and disposal requirements

- Licensed disposal facilities for hazardous and non-hazardous industrial waste

- Transportation compliance using properly licensed haulers and manifesting systems

- Recycling programs for materials that can be recovered and reused

- Cost optimization through waste minimization and efficient disposal practices

- Documentation that meets regulatory requirements and supports facility compliance