Tank Cleaning

Professional Tank Cleaning Services- Tierra Environmental

Expert Industrial Vessel Cleaning Solutions for Over Two Decades

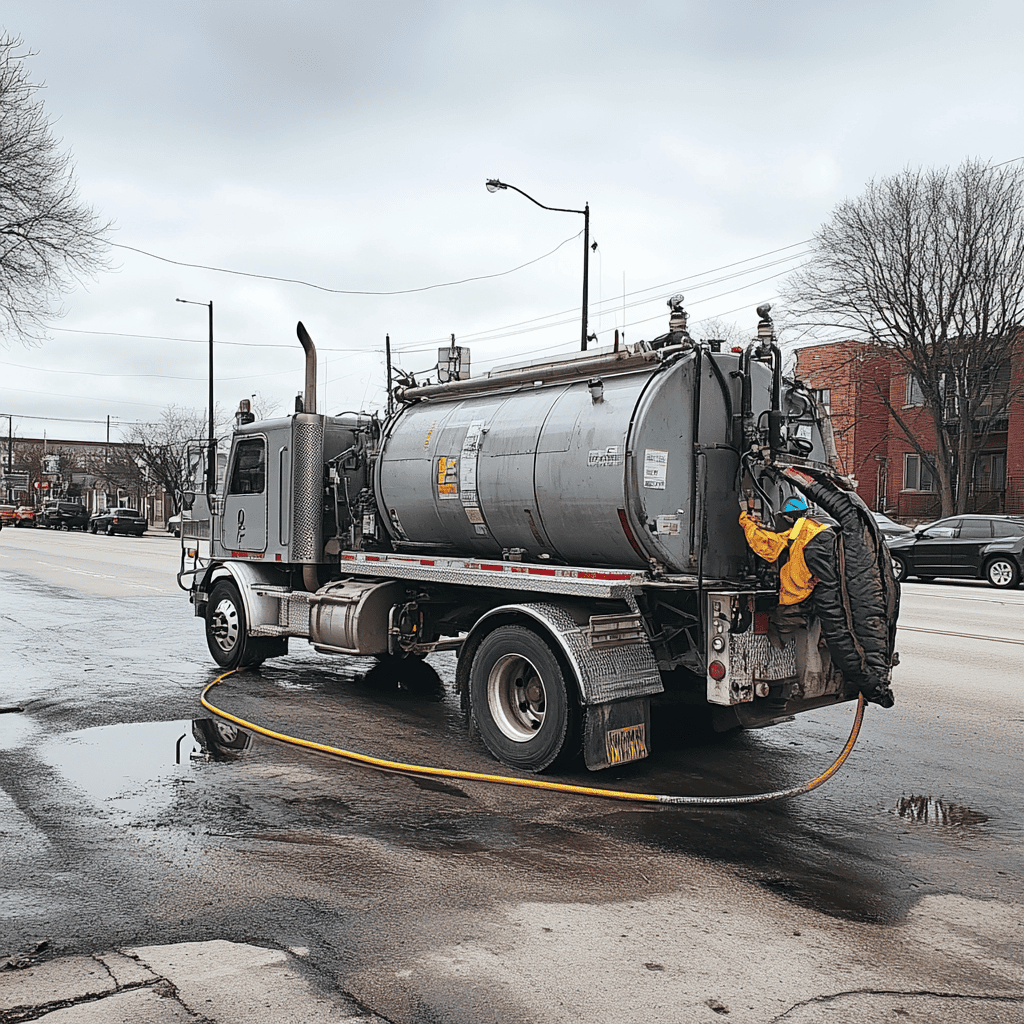

Tierra Environmental Services delivers professional tank cleaning services throughout Indiana and the Midwest region, specializing in the thorough cleaning of storage tanks, process vessels, and industrial containers across diverse industries. Our certified technicians utilize advanced cleaning methods, including high-pressure water jetting, chemical cleaning, and confined space entry procedures to remove residues, scale, and contaminants that impair tank performance and product quality. With extensive experience serving chemical processing plants, food manufacturers, petroleum facilities, and water treatment operations, we provide safe and efficient tank cleaning solutions that restore vessels to operational standards while maintaining regulatory compliance and worker safety.

GOODTrustindex verifies that the original source of the review is Google. Whether you need car wash pits sucked out, grease traps cleaned and jetted or any other services provided by Tierra Environmental expect no less than excellent expert service every time. Need assistance in choosing the right equipment and crew? Ask for Ralph. Caught in a pinch where time is a factor? Raplh is your guy. You can always count on Ralph getting the job done no matter the challenge. Happy customer for 10+ yearsTrustindex verifies that the original source of the review is Google. I have used Tierra Environmental for many years to help us pump out catch basins, triple basins and storm drains. They have always been on time and done a great job. If you need any basins pumped out ask for Ralph. He will take good care of you.Trustindex verifies that the original source of the review is Google. Great company great service. Great employees I would recommend them to anybody looking for ServiceTrustindex verifies that the original source of the review is Google. Ralph at Tierra is always helpful, even in an emergency situation, he finds a way to get help to us. Excellent customer service, would highly recommend.Trustindex verifies that the original source of the review is Google. Great company to do business with. Very efficient and quick to respond. Good prices for their services. Will definitely use them again.Trustindex verifies that the original source of the review is Google. A great company to work with! We use them for vacuum, hydrojetting and camera services. Mainly after hours call outs. They are fast to respond to the call.Trustindex verifies that the original source of the review is Google. Emergency response- on several occasions my clients have needed jetted and pumped out to keep their carwash operating. Tierras emergency response is excellent.Trustindex verifies that the original source of the review is Google. What a great company to do business with! Their staff is very helpful and their rates are very reasonable.

Trust Tierra Environmental for All Your Cleaning Needs

Our dedicated team is ready to assist you with tailored solutions that meet your specific requirements. Reach out now for a consultation and let us help you maintain a clean, safe, and compliant facility!

Proven Expertise and Experience

Comprehensive and Versatile Services

Expansive Midwest Presence with National Capabilities

Don’t let neglect lead to costly repairs or compliance issues. Contact Tierra Environmental today to discuss your industrial cleaning needs and discover how our comprehensive services can enhance your operational efficiency and environmental compliance.

Send us a message

Why Professional Tank Cleaning Is Required for Industrial Operations

Our Tank Cleaning Services Include:

High-Pressure Water Jetting and Surface Preparation

Water jetting parameters are carefully selected based on tank materials, residue characteristics, and surface conditions to achieve thorough cleaning without causing damage. Our technicians adjust pressure, flow rate, and nozzle selection to match specific cleaning requirements while maintaining safety protocols for confined space operations. This precision approach ensures effective cleaning while protecting tank investments and maintaining structural integrity.

Chemical Cleaning and Decontamination

Decontamination procedures remove hazardous materials and toxic residues that could pose health risks to workers or contaminate future tank contents. We follow established protocols for chemical decontamination while providing air monitoring and safety measures that protect personnel throughout the process. This decontamination capability supports tank maintenance programs while enabling safe entry for inspection and repair activities.

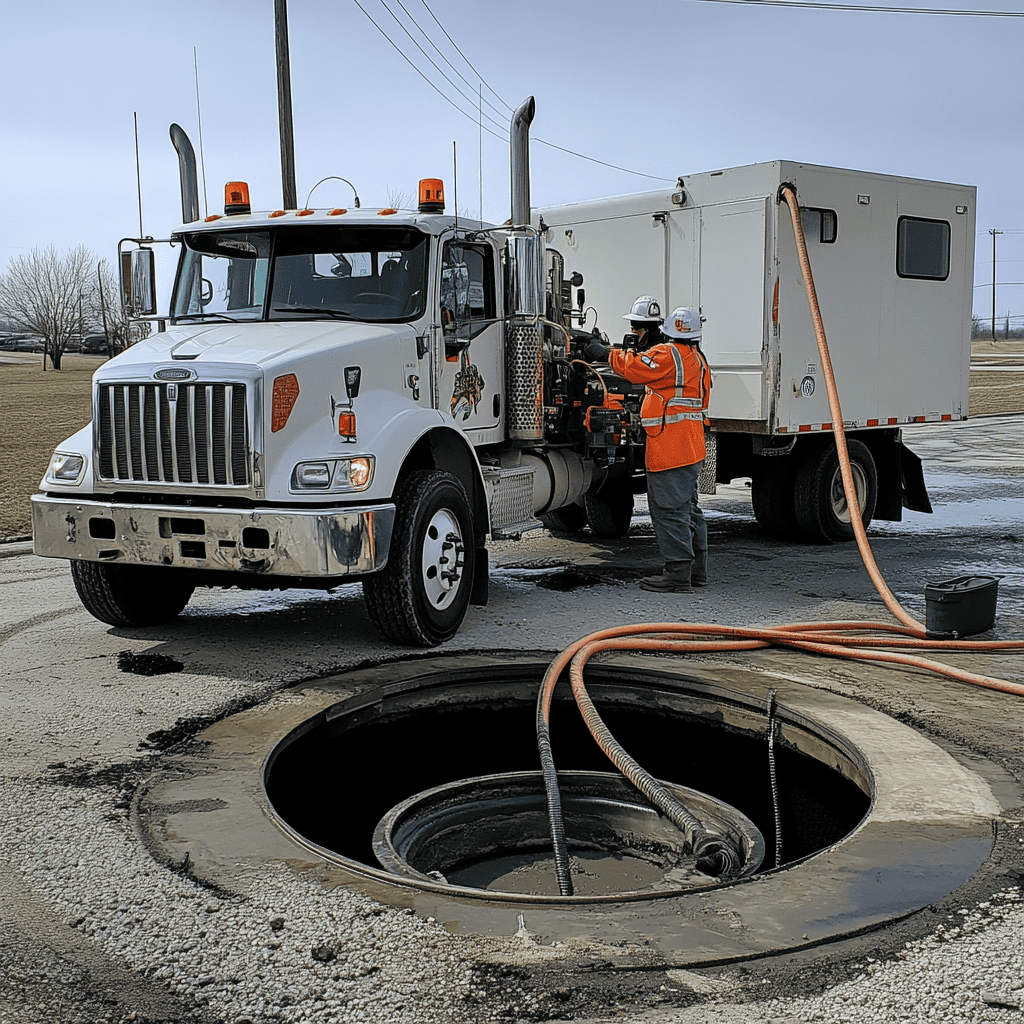

Confined Space Entry and Interior Cleaning

Interior cleaning includes manual removal of heavy deposits, cleaning of internal structures, and detailed surface preparation that external methods cannot achieve. Our technicians access all tank areas, including manholes, nozzles, and bottom surfaces while maintaining safety protocols and communication with support personnel. This hands-on approach ensures complete cleaning while supporting inspection activities and maintenance requirements.

Tank Inspection and Condition Assessment

Inspection activities include thickness measurements, weld examinations, and assessment of internal coatings or linings that protect tank integrity. We coordinate with customer personnel and third-party inspectors to provide access and documentation that supports API, ASME, and other industry standards for tank maintenance and certification. This inspection support reduces maintenance costs while ensuring safe and reliable tank operation.

Waste Management and Environmental Compliance

Environmental compliance includes permit requirements, discharge limitations, and documentation obligations that affect tank cleaning operations. We maintain expertise in applicable regulations while providing services that support customer environmental programs and permit compliance. This regulatory knowledge prevents violations while supporting positive relationships with environmental agencies and community stakeholders.

Trust Tierra Environmental for All Your Cleaning Needs

Benefits of Professional Tank Cleaning

Maintains Product Quality and Process Efficiency

Clean tanks operate more efficiently by providing full storage capacity, improved heat transfer, and reduced mixing requirements that lower energy costs and processing time. Removing deposits and scale improves tank performance while reducing wear on mixing equipment and heating systems. This efficiency improvement supports operational productivity while reducing maintenance costs and energy consumption.

Prevents Corrosion and Extends Equipment Life

Corrosion prevention through professional cleaning protects expensive tank investments while maintaining structural integrity that supports safe operation. Early removal of corrosive materials prevents damage that requires expensive repairs or premature replacement. This protection approach reduces total ownership costs while supporting long-term operational planning and budget management.

Supports Regulatory Compliance and Safety Standards

Safety standards, including OSHA confined space regulations, require specialized training and procedures that professional tank cleaning services provide. Our certified technicians follow established safety protocols while maintaining required documentation that demonstrates compliance during regulatory inspections. This safety compliance protects workers while reducing liability exposure and insurance costs.

Enables Thorough Inspection and Maintenance

Maintenance activities, including coating application, repair work, and equipment installation, require clean surfaces for proper adhesion and performance. Professional cleaning prepares tanks for maintenance work while providing documentation that supports warranty requirements and quality standards. This preparation reduces maintenance costs while ensuring the reliable performance of repair and upgrade work.

Reduces Environmental and Safety Risks

Environmental protection includes proper waste handling and disposal that prevents contamination of soil, groundwater, and air resources. Our environmental compliance expertise protects customers from liability while supporting sustainability programs and community relations. This environmental stewardship demonstrates corporate responsibility while maintaining regulatory compliance and public trust.

Understanding Tank Cleaning Methods and Technologies

Mechanical Cleaning Techniques and Equipment

Equipment selection depends on tank size, residue characteristics, and access conditions that affect cleaning efficiency and safety requirements. Large tanks may require multiple cleaning stations, while confined spaces need specialized portable equipment that technicians can maneuver safely. Our diverse equipment inventory includes various cleaning tools that match specific application requirements while maintaining safety and efficiency standards.

Chemical Cleaning Processes and Applications

Different industries require specific chemical cleaning approaches based on the materials they process and store. Food processing tanks need food-grade cleaning agents, while chemical tanks may require specialized solvents for specific contamination types. Our chemical expertise includes an understanding of compatibility issues and safety requirements that ensure effective cleaning while maintaining worker safety and environmental compliance.

Confined Space Safety and Entry Procedures

Safety equipment for confined space operations includes atmospheric monitors, ventilation systems, rescue equipment, and communication devices that protect workers while enabling efficient cleaning operations. Our technicians receive specialized training in confined space entry while maintaining current certifications that demonstrate competency in safety procedures. This safety expertise prevents accidents while supporting the efficient completion of cleaning operations.

Industries We Serve with Tank Cleaning Services

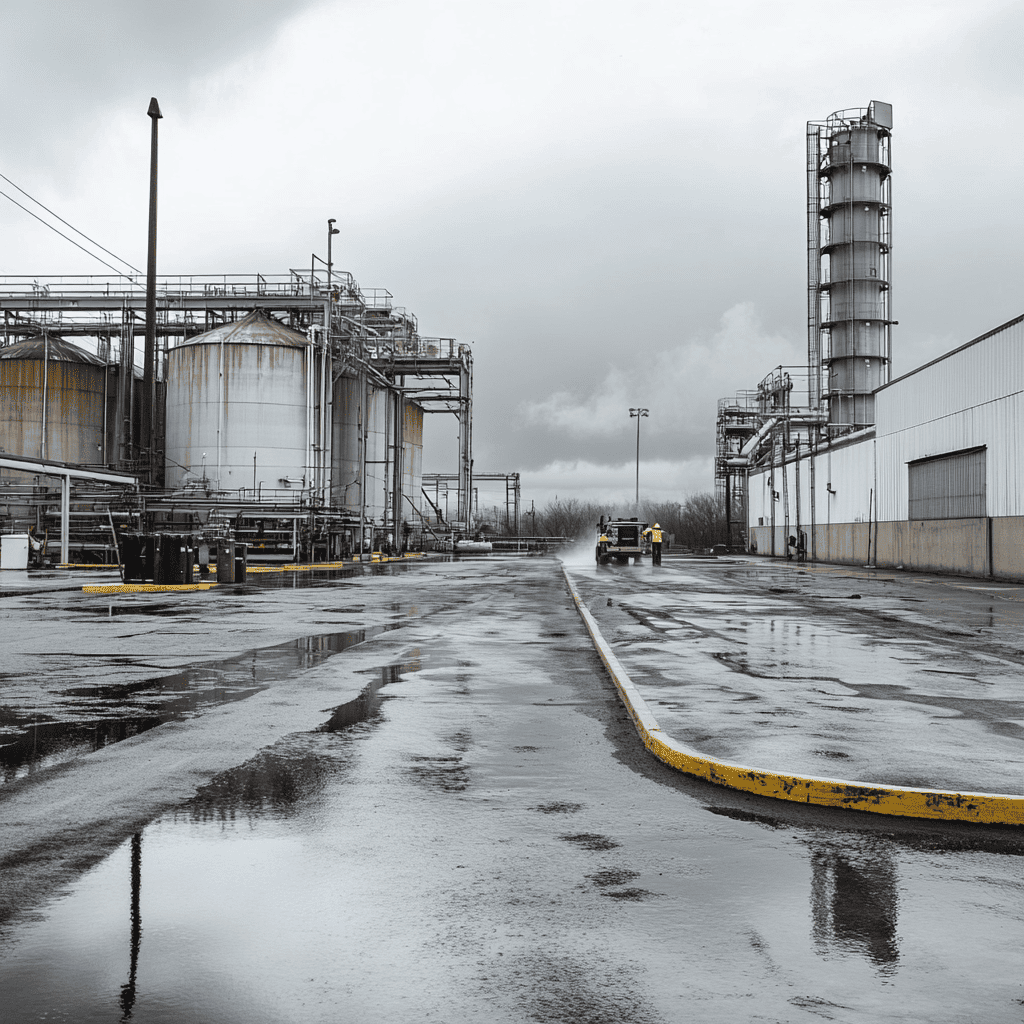

Chemical Processing and Petrochemical Facilities

Chemical processing facilities require specialized tank cleaning services that handle various chemical residues, reaction products, and contamination while meeting strict safety and environmental requirements. Our technicians possess hazmat certifications and chemical handling expertise necessary to safely clean vessels containing corrosive, toxic, or reactive materials. We follow industry-specific safety protocols while providing cleaning services that support chemical manufacturing operations and regulatory compliance.

Petrochemical facilities present unique challenges, including hydrocarbon residues, catalyst materials, and high-temperature deposits that require specialized cleaning methods and safety procedures. Our experience with petroleum products and chemical processes enables safe and effective cleaning of storage tanks, reactor vessels, and process equipment. This industry expertise supports facility maintenance programs while maintaining operational safety and environmental compliance.

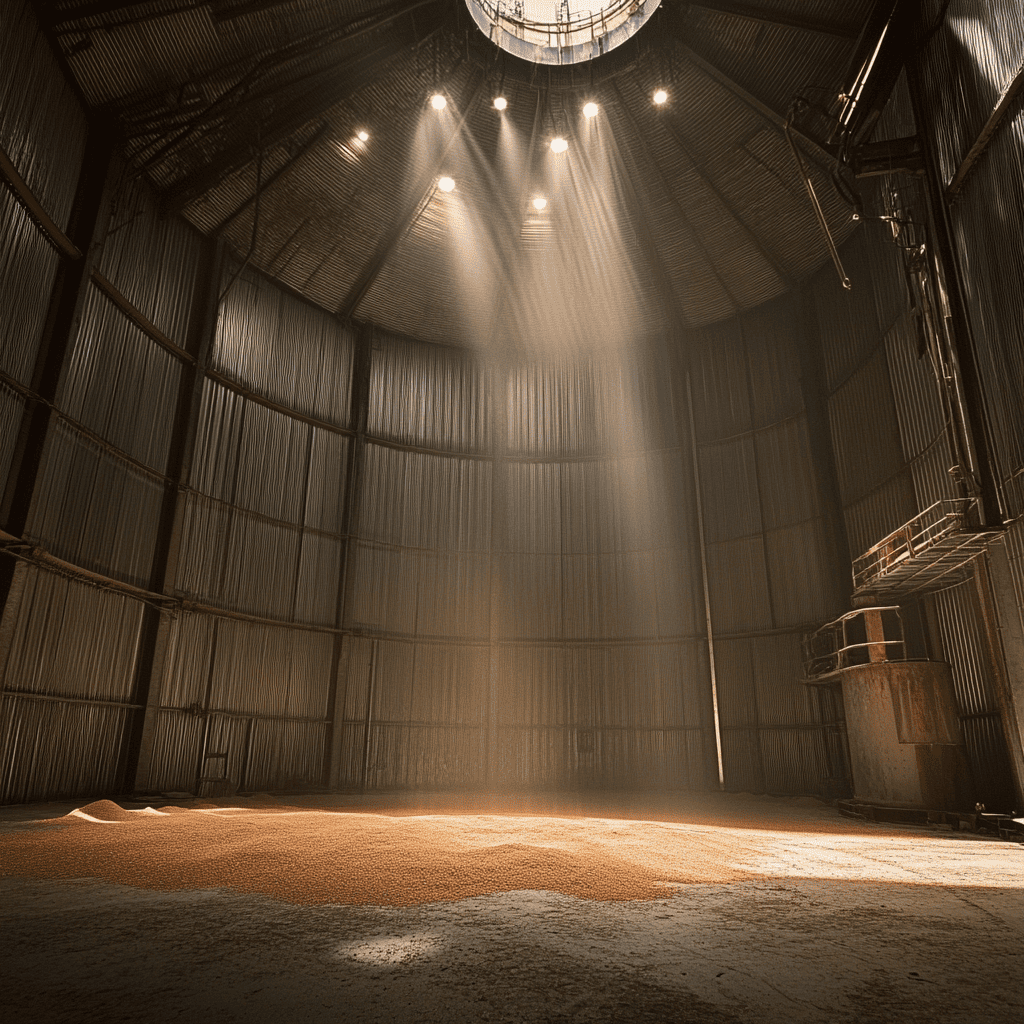

Food and Beverage Manufacturing

Beverage manufacturing, including breweries, wineries, and soft drink production, requires specialized cleaning that removes product residues, microbial contamination, and mineral deposits while maintaining sanitary conditions. Our technicians understand beverage industry cleaning requirements while providing services that support quality programs and regulatory compliance. This expertise ensures cleaning effectiveness while maintaining product safety and quality standards.

Pharmaceutical and Biotechnology Operations

Biotechnology operations, including fermentation tanks and bioreactor vessels, require specialized cleaning that removes biological materials while preventing contamination that could affect product quality or compromise sterility. Our technicians understand bioprocessing requirements while providing cleaning services that support biotechnology manufacturing and research operations. This expertise ensures appropriate cleaning while maintaining critical process conditions.

Water and Wastewater Treatment

Wastewater treatment facilities, including digesters, clarifiers, and storage tanks, require cleaning services that handle various contaminants while maintaining treatment efficiency and environmental compliance. Our technicians understand wastewater treatment processes while providing cleaning services that support system performance and regulatory requirements. This expertise ensures effective cleaning while maintaining treatment effectiveness and environmental protection.

Tank Cleaning Safety Requirements and Procedures

Atmospheric Testing and Hazard Assessment

Hazard assessment includes evaluation of tank contents, cleaning chemicals, and potential reactions that could create safety risks during cleaning operations. We review material safety data sheets while consulting with customer personnel to understand specific hazards and safety requirements. This assessment approach identifies potential problems while developing safety procedures that protect workers and prevent accidents.

Personal Protective Equipment and Safety Systems

Safety systems, including ventilation equipment, atmospheric monitors, and emergency response equipment, provide additional protection during tank cleaning operations. We maintain safety equipment according to manufacturer’s specifications while providing regular training that ensures proper use and maintenance. This equipment approach supports worker safety while meeting regulatory requirements for confined space operations.

Emergency Response and Rescue Procedures

Rescue procedures for confined space operations require specialized equipment and training that enable safe removal of personnel from tank environments. Our technicians receive rescue training while maintaining the required equipment that supports emergency response capabilities. This emergency preparedness protects workers while meeting regulatory requirements for confined space operations.

Trust Tierra Environmental for All Your Cleaning Needs

Tank Cleaning Process and Quality Assurance

Pre-Cleaning Assessment and Planning

Planning activities include equipment selection, chemical specification, and scheduling coordination that accommodates customer operations while meeting cleaning objectives. We develop written procedures that address safety requirements, cleaning methods, and quality standards while coordinating with customer personnel and regulatory agencies as required. This planning approach ensures successful project completion while maintaining safety and compliance standards.

Systematic Cleaning and Quality Control

Cleaning verification includes post-cleaning inspection and testing that confirms the removal of target contaminants while meeting customer specifications and regulatory requirements. We provide analytical services, including residue testing and surface cleanliness verification, that demonstrate cleaning effectiveness. This quality assurance approach ensures customer satisfaction while supporting regulatory compliance and operational requirements.

Documentation and Compliance Reporting

Compliance reporting includes safety documentation, waste disposal records, and certification statements that support regulatory inspections and permit requirements. We maintain records according to regulatory requirements while providing customer access to documentation that supports their compliance programs. This documentation approach protects customers while demonstrating professional service quality and regulatory compliance.

Specialized Tank Cleaning Applications

Storage Tank Cleaning and Maintenance

Storage tank cleaning often requires coordination with inspection activities, coating application, and repair work that extends tank service life while maintaining operational reliability. Our scheduling flexibility accommodates maintenance programs while providing cleaning services that support inspection access and surface preparation requirements. This coordination approach reduces project costs while ensuring the successful completion of maintenance activities.

Process Vessel and Reactor Cleaning

Process vessel cleaning often requires quick turnaround to minimize production downtime while ensuring thorough cleaning that prevents contamination issues. Our responsive service capabilities include expedited scheduling and additional resources that reduce cleaning time while maintaining quality standards. This efficiency approach supports customer production schedules while ensuring cleaning effectiveness and operational reliability.

Specialty Applications and Custom Solutions

Custom cleaning solutions may include specialized equipment, unique chemical applications, or modified procedures that address specific customer requirements or regulatory standards. Our engineering capabilities include equipment modification and procedure development that enables the cleaning of challenging applications. This custom approach ensures successful cleaning while supporting customer operational requirements and compliance obligations.

Environmental Considerations and Sustainability

Waste Minimization and Resource Conservation

Resource conservation includes water recycling, chemical recovery, and energy-efficient cleaning methods that reduce environmental impact while maintaining cleaning effectiveness. We evaluate opportunities for resource conservation while implementing practices that support environmental responsibility and cost reduction. This conservation approach demonstrates environmental stewardship while providing economic benefits to customers.

Regulatory Compliance and Environmental Protection

Environmental protection includes spill prevention, air emissions control, and proper waste handling that prevents contamination of soil, water, and air resources. Our environmental procedures include monitoring, containment, and response measures that protect environmental quality while meeting regulatory requirements. This protection approach supports customer environmental responsibility while maintaining regulatory compliance and community relations.

Trust Tierra Environmental for Professional Tank Cleaning

Our comprehensive approach to tank cleaning includes safety planning, environmental compliance, and quality assurance that ensures successful project completion while exceeding customer expectations. Let our experienced team handle your tank cleaning requirements so you can focus on core operations while maintaining equipment reliability and regulatory compliance.

Trust Tierra Environmental for All Your Cleaning Needs

Frequently Asked Questions

What types of tanks and vessels can you clean?

- Storage tanks include crude oil, product, and chemical storage

- Process vessels such as reactors, mixing tanks, and heat exchangers

- Food processing tanks, including fermentation and mixing vessels

- Water treatment tanks, including clarifiers and storage vessels

- Pharmaceutical equipment, including bioreactors and process tanks

- Specialty vessels including silos, hoppers, and custom equipment

Do you provide confined space entry for interior tank cleaning?

- OSHA-certified personnel with confined space entry permits

- Atmospheric testing and continuous air monitoring

- Emergency rescue procedures and equipment

- Ventilation systems for maintaining safe atmospheres

- Communication systems between entry and attendant personnel

- Personal protective equipment appropriate for specific hazards

What cleaning methods do you use for different types of contamination?

Mechanical Cleaning:

- High-pressure water jetting for scale and deposits

- Rotating tank cleaners for systematic surface coverage

- Manual cleaning for detailed surface preparation

Chemical Cleaning:

- Acid cleaning for mineral scale and metal oxides

- Solvent cleaning for organic residues and oils

- Alkaline cleaning for biological materials and proteins

Specialized Methods:

- Steam cleaning for temperature-sensitive applications

- Abrasive cleaning for stubborn coatings and deposits

How do you handle hazardous materials during tank cleaning?

- Material characterization through sampling and analysis

- Personal protective equipment appropriate for specific hazards

- Atmospheric monitoring throughout cleaning operations

- Containment measures to prevent environmental releases

- Proper disposal at licensed hazardous waste facilities

- Documentation meeting regulatory requirements

What documentation do you provide after tank cleaning?

- Before-and-after photographs showing cleaning results

- Analytical testing data for cleanliness verification

- Safety documentation, including atmospheric test results

- Waste disposal records and certificates

- Cleaning procedures and methods used

- Compliance certification meets regulatory requirements

Can you coordinate tank cleaning with inspection and maintenance activities?

- API tank inspections require clean surfaces for examination

- Coating application needs proper surface preparation

- Repair work requires clean and safe working conditions

- Equipment installation in clean tank environments

- Regulatory inspections with required documentation

How long does tank cleaning typically take?

- Tank size and configuration complexity

- Contamination type and deposit thickness

- Cleaning method and equipment requirements

- Safety requirements for confined space operations

- Access limitations and logistical considerations

- Quality standards and inspection requirements

What safety measures do you implement during tank cleaning operations?

- Pre-entry atmospheric testing for all hazardous conditions

- Continuous air monitoring throughout operations

- Emergency response planning with rescue procedures

- Personal protective equipment selection based on hazard assessment

- Safety training for all personnel involved in operations

- Communication systems between entry teams and attendants

Do you provide emergency tank cleaning services?

- 24-hour availability for urgent situations

- Rapid deployment of equipment and personnel

- Emergency containment and cleanup services

- Regulatory coordination for incident response

- Documentation for insurance and regulatory reporting